Unleash the Power of Full Face Gaskets for Superior Leak Prevention

23 April 2024

Unleash superior leak prevention with full face gaskets from Gasketech. Explore their benefits and applications for reliable sealing in industrial applications.

Reliable sealing from full face gaskets and others is essential for preventing leaks, contamination, and downtimes, which can only result in costly repairs and production losses. Full face gaskets are a significant component of industrial systems as they provide a secure and effective barrier against fluid and gas leakage in a wide range of applications.

A Quick Look at Full Face Gaskets

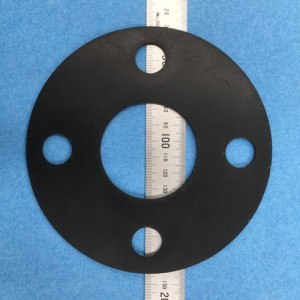

Full face gaskets are sealing devices designed to create a tight and leak-proof seal between two flat surfaces, such as flanges, pipes, or machinery components. Unlike ring gaskets that only cover the flange sealing surface, full face gaskets extend across the entire face of the flange, providing complete coverage and sealing protection. These gaskets are typically made from flexible materials such as rubber, silicone, PTFE (Teflon), or graphite, which are chosen based on the specific application requirements and operating conditions.

Currently, Gasketech offers full face gaskets to businesses requiring proper sealing protection for their respective industrial systems. Some notable applications of our full face gaskets include piping systems, pressure vessels, heat exchangers, pumps, compressors, and engines.

Main Benefits of Full Face Gaskets

Full face gaskets offer several benefits for industrial sealing applications.

• Comprehensive Sealing: By covering the entire face of the flange, full face gaskets provide a complete and uniform seal, reducing leaks and ensuring reliable containment of fluids and gases.

• Enhanced Stability: Full face gaskets distribute sealing pressure evenly across the flange surface, which promotes stability and prevents distortion or damage to the sealing interface.

• Resistance to Compression Set: High-quality full face gaskets are engineered to resist compression set, maintaining their sealing integrity over extended periods of use and under varying pressures and temperatures.

• Cost-Effective: Aside from their superior sealing performance, full face gaskets are often cost-effective compared to alternative solutions, offering excellent value for money.

• Remarkable Versatility: Full face gaskets are available in a wide range of materials, sizes, and configurations to accommodate different flange designs, operating temperatures, and chemical compatibility requirements.

Proper Installation and Maintenance

To maximise the effectiveness of full face gaskets, proper installation and maintenance practices must be done. Flange surfaces, for one, must be clean, flat, and free from defects or damage that could compromise the sealing integrity. Additionally, they should be installed with the correct torque and compression to achieve the desired level of sealing performance. Regular inspections and replacements of full face gaskets are then recommended to address wear, deterioration, or damage over time and maintain reliable sealing in industrial systems.

Full face gaskets from Gasketech can ensure superior leak prevention and reliable sealing in industrial settings. With their comprehensive coverage, stability, versatility, and cost-effectiveness, they offer an effective solution for sealing flanged connections, piping systems, and other critical components.

By unleashing the power of full face gaskets, your industrial facility can minimise the risk of leaks, contamination, and downtime, guaranteeing safe and efficient operation while maximising productivity and profitability. With proper installation, maintenance, and selection of high-quality gasket materials, your business can then achieve dependable sealing performance and peace of mind.

Optimized by: Netwizard SEO