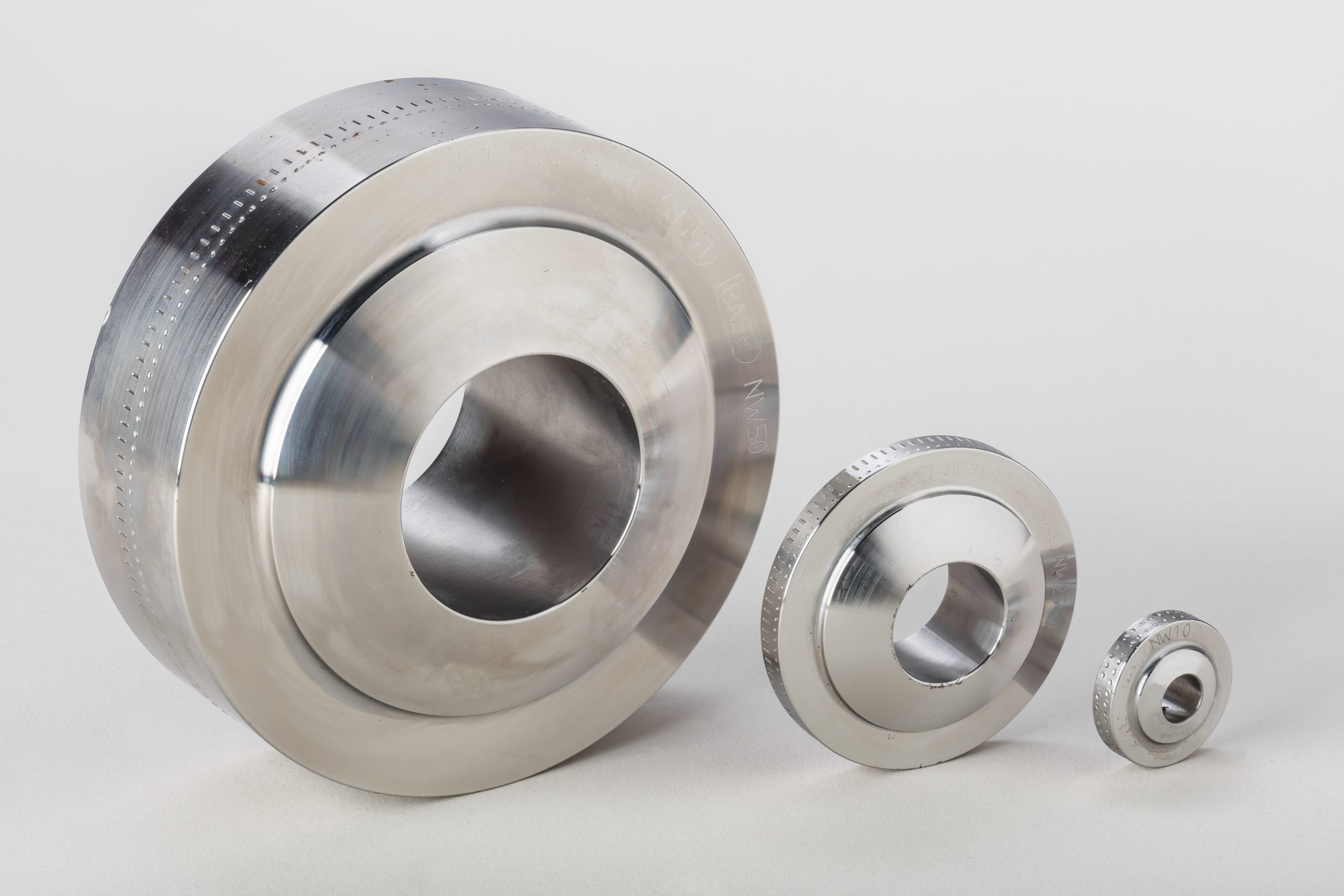

Graphite/Stainless Steel Gaskets for the Food and Pharmaceutical Industries

19 February 2024Elevate hygiene in food and pharmaceutical industries with graphite/stainless steel gaskets. Available at Gasketech, ensure safety today. Call (03) 9690 2577.

Food, pharmaceutical, and biotech manufacturing industries are highly regulated industries that require the right equipment and tools to ensure the success of their operations. Without opting for these things, they may compromise the safety of their products, which can then cause harm to people. Now, one component that should be present on equipment and tools used for these industries is the gasket.

Gaskets help create a tight seal between two or more surfaces, preventing the leakage of fluids or gases. They also ensure the efficient and safe operation of machinery. While many materials can be used to fabricate gaskets, those intended for the food and pharmaceutical industries must be made from graphite/stainless steel due to the following reasons.

High Degree of Purity

Graphite/stainless steel gaskets exhibit a high degree of purity. Gaskets made from graphite and stainless steel do not introduce impurities or contaminants into the systems they are sealing, which makes them suitable for food processing, pharmaceuticals, and biotech manufacturing.

Ensured Cleanliness

The smooth and non-porous surface of graphite/stainless steel materials contributes to the cleanliness of the gaskets. They lack surface irregularities or microscopic pores, which helps minimise the likelihood of trapping particles or fostering bacterial growth. This quality makes these gaskets an effective sealing solution without compromising cleanliness standards.

Chemical Resistance

Graphite/stainless steel gaskets are known for their excellent resistance to a wide range of chemicals. The inherent chemical inertness of graphite and stainless steel allows these gaskets to withstand exposure to corrosive substances, acids, and bases.

Steam Resistance

Aside from being resistant to chemicals, graphite/stainless steel gaskets also exhibit impressive resistance to steam, making them compatible with applications that involve high-temperature and high-pressure steam conditions. The robust nature of these materials allows them to maintain their structural integrity and sealing properties even when exposed to steam.

High-Temperature Stability

Food, pharmaceutical, and biotech manufacturing industries often carry out their operations at high temperatures. Graphite and stainless steel, fortunately, have a high melting point and excellent thermal stability. This property allows gaskets made from the said materials to maintain their integrity and sealing effectiveness at elevated temperatures.

Conformability and Sealing Efficiency

Graphite and stainless steel have the ability to conform to irregular surfaces, enhancing the sealing efficiency of gaskets made from these materials. Even under varying pressures and temperature fluctuations, these gaskets can maintain a tight seal, preventing leaks and ensuring the integrity of the equipment and tools.

Anti-Stick Characteristics

Graphite and stainless steel gaskets have anti-stick characteristics that make their installation and removal smoother. This property reduces the risk of damage during maintenance or replacement of parts and components.

All properties of graphite/stainless steel gaskets make them a preferred choice in industries where maintaining a sterile environment, chemical resistance, and reliable sealing performance are significant. Whether used in pharmaceutical manufacturing, food processing, or high-temperature applications, graphite/stainless steel gaskets from Gasketech offer a combination of properties that contribute to their effectiveness and versatility across various settings.

Optimized by: Netwizard SEO