Why Graphite Gaskets Are Ideal for High-Pressure Industrial Applications

27 November 2024Discover why graphite gaskets are the go-to choice for high-pressure industrial applications. Know key applications that can take advantage of these gaskets.

Graphite gaskets are increasingly recognised as the ideal sealing solution for high-pressure industrial applications due to their exceptional properties. These gaskets excel in environments where extreme temperatures and corrosive substances are prevalent, making them indispensable in sectors like oil and gas, power generation, and chemical processing.

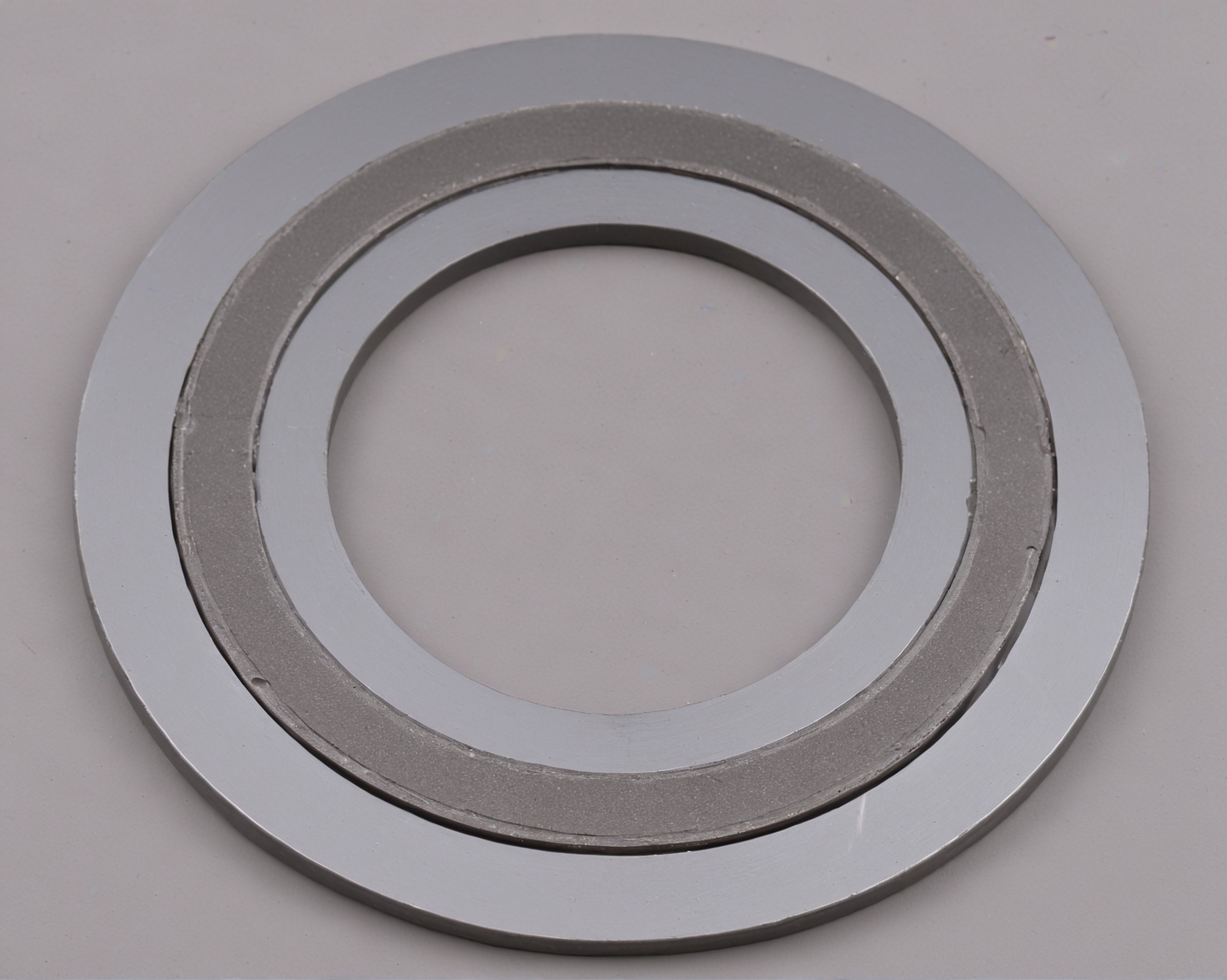

What are Graphite Gaskets?

Graphite gaskets are sealing components made from flexible graphite material, known for their excellent heat resistance, chemical stability, and low friction properties. These gaskets effectively create a tight seal between surfaces, preventing leaks of gases or liquids. Their durability and resilience make them suitable for various environments, including those with corrosive substances, ensuring long-lasting performance in demanding conditions.

These gaskets are often produced by selecting high-purity graphite, which is then compressed into sheets using hydraulic presses. These sheets are cut to specific sizes and shapes, tailored for various industrial applications. After cutting, the gaskets undergo finishing processes, such as surface smoothing or coating, to improve sealing capabilities.

Finally, rigorous quality control tests are conducted to ensure that the gaskets meet industry standards, resulting in a reliable product that can withstand high pressures and extreme conditions effectively.

Why Choose Graphite Gaskets?

Graphite gaskets are ideal for high-pressure industrial applications for several compelling reasons:

• High-Temperature Resistance: Graphite can withstand extreme temperatures, which makes it suitable for applications in environments where heat is a concern. This property helps maintain sealing integrity, even under fluctuating thermal conditions.

• Low Friction Properties: Graphite has natural lubricity that allows for easy installation and removal of gaskets, reducing wear on equipment during maintenance. It also minimises friction between moving parts, contributing to overall efficiency in mechanical systems.

• Chemical Stability: Graphite gaskets resist a wide range of chemicals, including acids and bases, making sure they can function in aggressive environments without degrading.

• Thermal Conductivity: Graphite possesses good thermal conductivity, which helps dissipate heat away from critical areas and prevent overheating.

• Excellent Compressibility: The flexible nature of graphite allows for effective compression, enabling these gaskets to fill imperfections on sealing surfaces. This compressibility helps create a tight seal, reducing the risk of leaks even under high pressure.

• Long Lifespan: Due to their durability and resistance to wear, graphite gaskets have a longer operational life compared to traditional materials. This longevity reduces the frequency of replacements, saving costs and downtime in industrial operations.

When to Use Graphite Gaskets?

These previously stated attributes make graphite gaskets a preferred choice for ensuring reliable and efficient sealing in high-pressure environments. Some high-pressure industrial applications that can maximise graphite gaskets are as follows.

• Oil and Gas Industry: Graphite gaskets can be used in pipelines and drilling equipment, where they must withstand extreme pressures and corrosive substances.

• Power Generation: Graphite gaskets can also be used in boilers and turbines as they can withstand high temperatures and pressures.

• Chemical Processing: Reactors and storage tanks are likewise equipped with graphite gaskets to handle aggressive chemicals safely.

• Marine Applications: Graphite gaskets are employed in ship engines and systems so they can provide reliable sealing under varying pressures and temperatures.

Invest in graphite gaskets from Gasketech today to maintain the sealing integrity of your high-pressure industrial operations. Reduce the risks of leaks and equipment failures with these gaskets.

Optimized by: Netwizard SEO