The Role of Full Face Gaskets in Sustainable Australian Manufacturing

11 June 2024Discover how full face gaskets from Gasketech contribute to sustainable manufacturing in Australia. Optimise your operations today.

As people all around the world become more aware of the importance of sustainable living, businesses in Australia are stepping up to the plate. One often overlooked aspect of sustainable manufacturing is choosing high-quality, durable parts that reduce waste and improve efficiency.

Gaskets, in particular, play a key role in this regard, and Gasketech is leading the way in offering innovative solutions for Australian manufacturers.

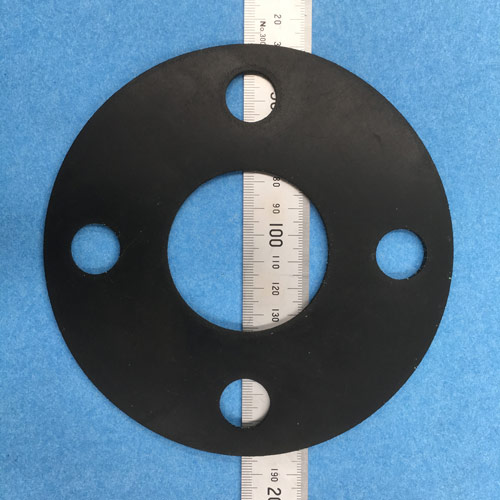

What are Full Face Gaskets?

Full face gaskets are sealing devices designed to create a tight, leak-proof connection between two flanged surfaces, such as those found in pipework, tanks, and vessels. Unlike traditional gaskets, which only seal the bolt holes, full face gaskets extend across the entire surface of the flange, providing a more comprehensive seal and reducing the risk of leaks and failures.

The Benefits of Full Face Gaskets for Sustainable Manufacturing

• Improved Sealing Performance: Full face gaskets offer superior sealing capabilities compared to traditional gaskets, reducing the risk of leaks and minimising the potential for environmental contamination.

• Increased Durability: Gasketech’s full face gaskets are manufactured using high-quality materials and advanced production techniques, ensuring long-lasting performance and reduced maintenance requirements.

• Reduced Waste: By minimising leaks and extending the lifespan of equipment, full face gaskets help to reduce waste and conserve valuable resources, contributing to a more sustainable manufacturing process.

• Compliance with Australian Standards: Gasketech’s full face gaskets are designed and manufactured to comply with the relevant Australian Standards, ensuring that your operations meet the necessary safety and environmental regulations.

• Cost Savings: While the initial investment in full face gaskets may be higher than in traditional gaskets, the long-term cost savings in terms of reduced maintenance, downtime, and waste can be significant.

Gasketech: Your Partner in Sustainable Manufacturing

At Gasketech, we are committed to providing Australian manufacturers with the tools they need to succeed in a sustainable future. Our full face gaskets are just one example of our innovative approach to sealing solutions, designed to optimise performance, reduce waste, and enhance the overall efficiency of your manufacturing operations.

Our team of experienced engineers works closely with clients to understand their unique requirements and develop customised solutions that meet their needs. We use advanced materials and production techniques to ensure the highest quality and performance, and our commitment to customer service is unparalleled.

Invest in the Future of Australian Manufacturing

As Australian manufacturers strive to meet the challenges of sustainability, investing in high-quality components like full face gaskets from Gasketech is a smart move. By optimising your sealing solutions, you can reduce waste, improve efficiency, and contribute to a more sustainable future for the Australian manufacturing industry.

Gasketech’s commitment to sustainability goes beyond just our products. We prioritise environmentally friendly practices throughout our entire operation, from sourcing materials to manufacturing processes and packaging.

By choosing Gasketech, you’re aligning yourself with a company that shares your values and is dedicated to creating a better, more sustainable future for generations to come.

Optimized by: Netwizard SEO