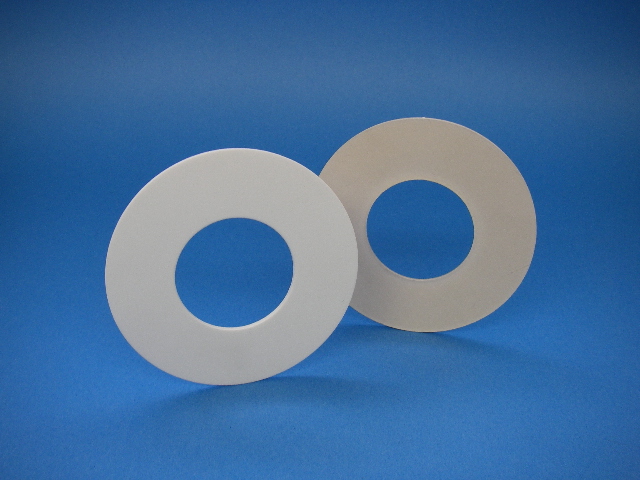

PTFE Ring Gaskets from Gasketech: The Go-To Solution for Critical Industries

06 March 2024Get to know PTFE ring gaskets, the go-to solution for critical industries. Available at Gasketech, learn how they ensure reliable sealing in demanding settings.

PTFE or polytetrafluoroethylene ring gaskets have emerged as the go-to solution in critical industries. With their exceptional chemical resistance, temperature tolerance, and sealing capabilities, PTFE ring gaskets are widely used in applications that prioritise safety, performance, and reliability.

PTFE Ring Gaskets: Basic Composition

PTFE is a synthetic fluoropolymer known for its unique combination of properties, which includes low friction, high-temperature resistance, chemical inertness, and a non-adhesive surface. Ring gaskets made from this material are typically produced by compressing PTFE material into a ring shape, often with a filler material such as glass fibre or carbon added to enhance mechanical properties.

Notable Qualities of PTFE Ring Gaskets

The composition of PTFE ring gaskets enables them to boast the following qualities.

• Unparalleled Chemical Resistance: PTFE ring gaskets offer unparalleled resistance to a lot of chemicals, acids, solvents, and corrosive fluids. This resistance helps them ensure reliable sealing in aggressive environments.

• Supreme Temperature Tolerance: PTFE ring gaskets can also withstand extreme temperatures ranging from cryogenic to high heat, which makes them suitable for applications involving rapid temperature changes and thermal cycling.

• Simplified Installation: PTFE’s non-adhesive surface prevents gaskets from sticking and galling, facilitating easy installation, removal, and maintenance of sealing systems.

• Low Friction Property: PTFE ring gaskets boast a low coefficient of friction, allowing them to reduce wear and frictional losses in sealing applications, extend the service life of the equipment and reduce overall energy consumption.

• Long Service Life: PTFE ring gaskets have a long service life due to their durability, resilience, and resistance to degradation, which minimises the need for frequent replacements and downtime.

Key Applications of PTFE Ring Gaskets

PTFE ring gaskets are used to create a reliable seal between two mating surfaces in a wide range of industrial applications. Some of these applications are as follows.

• Chemical Processing: PTFE gaskets provide exceptional resistance to chemicals, acids, and corrosive fluids encountered in chemical processing plants. They are used in flange connections, pipe joints, and equipment seals to prevent leaks and contamination.

• Food and Beverage: PTFE gaskets are utilised in food and beverage processing facilities to seal equipment and piping used in the production, storage, and distribution of food products. Their non-toxic, non-stick properties make them suitable for applications requiring hygienic sealing and compliance with regulatory standards.

• Oil and Gas: PTFE gaskets are also maximised in oil and gas production, refining, and transportation facilities to seal pipeline connections, valves, and pressure vessels. Their resistance to hydrocarbons, solvents, and high pressures ensures reliable sealing in harsh operations.

• Pharmaceuticals and Biotechnology: PTFE gaskets are preferred in pharmaceutical and biotech applications due to their purity, non-contaminating properties, and compliance with regulations. They are used in equipment seals, sterile processing, and fluid handling systems to maintain product integrity and safety.

PTFE ring gaskets, which are available at Gasketech in various dimensions and specifications, serve as the go-to solution for critical industries that require reliable sealing. With their exceptional qualities, these gaskets provide reliable sealing in demanding applications in chemical processing, oil and gas, pharmaceuticals, food and beverage, or other critical sectors.

Optimized by: Netwizard SEO