Non-Asbestos Fibre Gaskets: High-Temperature Supply for Mechanical Service Contractors

04 February 2026

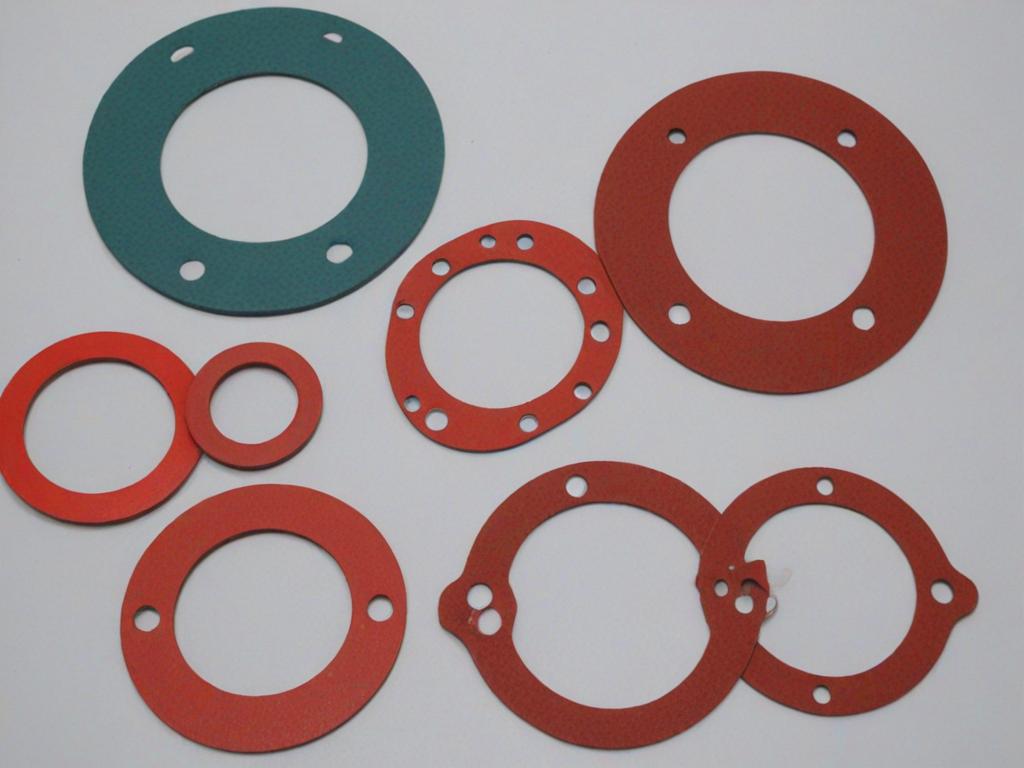

Solve high-temp sealing demands using non-asbestos fibre gaskets from Gasketech in Melbourne, providing reliable performance for mechanical contractors.

High-temperature sealing materials support the safe operation of many industrial systems used by mechanical service contractors. Non-asbestos fibre gaskets deliver consistent sealing performance that withstands heat, pressure, and constant vibration. These materials hold their structure in demanding environments where long operating cycles and thermal change affect standard gasket products.

Properties That Support Long-Term Sealing Performance

Modern gasket designs use reinforced fibres and heat-resistant binders to maintain a stable seal in high-temperature or high-pressure applications. The material stays firm through repeated thermal cycling, which helps protect sealing surfaces during system start-up and shutdown. These characteristics allow contractors to work with confidence when servicing boilers, process lines, and circulating pump systems.

Dimensional stability also contributes to lower maintenance needs because the gasket does not compress unevenly under load. Reduced deformation supports long-term sealing accuracy, even in equipment that operates for extended hours. Mechanical ventilation units, heat exchangers, and commercial heating systems benefit from a gasket material that remains consistent throughout its service life.

Advantages of Using Non-Asbestos Fibre Gaskets for Contractors

Reliable gasket materials help improve the performance of many components found in industrial and commercial facilities. Strong sealing behaviour assists in preventing energy loss, fluid leakage, and unscheduled equipment shutdown. The features below highlight the engineering benefits offered by these gasket types.

Material strengths include:

• Thermal Capacity: Retains its sealing surface during continuous or fluctuating heat exposure in steam lines, hot-water circuits, and high-temperature mechanical equipment.

• Chemical Resistance: Maintains structure when exposed to oils, refrigerants, mild acids, and common process fluids used in industrial and HVAC systems.

• Pressure Stability: Holds uniform compression at high internal pressures, supporting safe operation in pump stations, process pipework, and commercial heating systems.

• Abrasion Tolerance: Reduces wear on sealing surfaces during vibration, flange movement, or repeated mechanical tightening in active plant environments.

• Reliable Fit: Ensures accurate seating between machined faces due to precise manufacturing tolerances that enhance sealing efficiency.

Applications Supporting Mechanical Service Work

Many industries rely on gasket materials that can be installed quickly and perform well across a range of plant conditions. Non-asbestos fibre gaskets integrate easily into new builds, repairs, and routine maintenance carried out by mechanical service contractors. This flexibility allows teams to manage sealing demands efficiently across various equipment types.

Common industrial applications:

• HVAC Heating and Cooling Systems: Delivers a stable seal for boiler housings, heat exchanger plates, and chilled-water assemblies that operate for extended periods.

• Hydraulic and Pump Assemblies: Maintains sealing accuracy in pumps, valves, and pressure-control equipment exposed to varying flow rates and loading cycles.

• Water Treatment Systems: Withstands constant flow, chemical contact, and ongoing system pressure within filtration units and distribution modules.

• Gas-Fired Industrial Equipment: Performs reliably in burner systems, gas manifolds, and exhaust chambers exposed to long-duration heat and combustion gases.

• Process Engineering Systems: Supports sealing in chemical lines, production circuits, and industrial machinery subject to frequent thermal and mechanical stress.

Reliable Supply for High-Temperature Industrial Conditions

Gasketech supplies durable non-asbestos fibre gaskets designed for demanding applications where thermal and mechanical forces are present. These solutions support contractors who require stable sealing performance in high-temperature and high-pressure environments. Our team provides reliable access to industrial sealing products engineered for long-term performance across commercial and mechanical service applications.

For specialised guidance or supply support, contact us to discuss the right gasket solution for your application.

Related Blog Article: Compressed Non-Asbestos Fibre Gaskets: Graphite Sealing for Automotive Hot Oil System

Optimized by: Netwizard SEO