Full Face Gaskets from Gasketech: Ensuring Maximum Protection Against Leaks

12 November 2024Full face gaskets from Gasketech offer superior leak protection across various industries in Melbourne. How these ensure efficiency in critical applications.

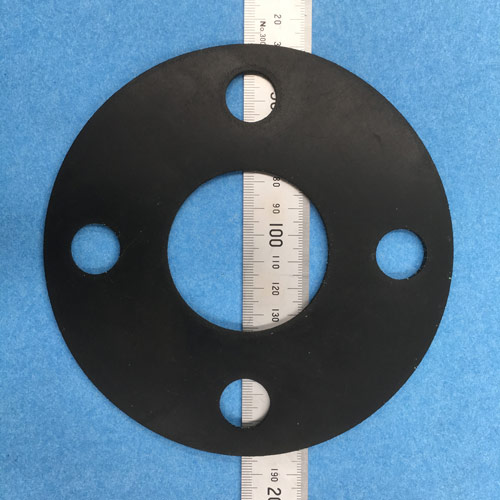

Full face gaskets are essential components for preventing leaks in various industrial applications. Their design covers the entire flange surface, providing superior sealing capabilities and enhancing system integrity. With a range of materials available, Gasketech’s full face gaskets ensure maximum protection against leaks, making them a reliable choice for industries like oil and gas, chemical processing, and water treatment.

Full Face Gaskets Overview

Full face gaskets are sealing components that cover the entire flange area of a joint. Unlike traditional gaskets that fit within the flange, full face gaskets provide a wider sealing surface, ensuring better contact and alignment. This design feature makes them particularly effective in applications where leakage prevention is critical. They are commonly used in industries such as oil and gas, chemical processing, and water treatment, where pressure and temperature fluctuations can lead to significant leakage issues.

Benefits of Full Face Gaskets

Full face gaskets from Gasketech are engineered to deliver exceptional performance and reliability in sealing applications. Their innovative design and versatile material options provide numerous advantages that enhance operational efficiency and safety. Below are some key benefits that make Gasketech’s full face gaskets an indispensable choice for various industries.

• Enhanced Sealing Performance: Full face gaskets offer superior sealing capabilities due to their larger surface area, which helps in distributing stress evenly. This characteristic minimises the risk of leakage, even under high-pressure conditions.

• Versatile Materials: Gasketech offers full face gaskets made from various materials catering to different application requirements. Each material is chosen based on its compatibility with specific fluids and operating environments.

• Reduced Installation Time: The design of full face gaskets simplifies installation. Their shape allows for easier alignment during the installation process, saving valuable time and reducing the likelihood of errors.

• Cost-Effectiveness: By preventing leaks, full face gaskets contribute to reduced downtime and maintenance costs. The longevity and reliability of Gasketech’s gaskets ensure that businesses save money in the long run by avoiding frequent replacements.

Key Considerations When Choosing Full Face Gaskets

When selecting full face gaskets for your application, it’s crucial to consider several key factors to ensure optimal performance and reliability.

• Material Compatibility: Ensure that the gasket material is compatible with the fluids or gases it will be exposed to. Using an incompatible material can lead to deterioration and potential leaks over time.

• Temperature and Pressure Ratings: Verify that the gasket can withstand the temperature and pressure conditions of your operation. Selecting a gasket with inadequate ratings may result in failure and costly downtime.

• Flange Specifications: Measure your flanges accurately to ensure a proper fit for the full face gasket. An incorrect size can compromise the seal, leading to leaks and system inefficiencies.

• Environmental Factors: Consider any external environmental factors that could impact gasket performance, such as exposure to chemicals or extreme weather conditions. Understanding the environment helps in selecting a gasket that will maintain its integrity and longevity.

Full face gaskets from Gasketech provide a robust solution for leak prevention in a variety of industrial applications. By choosing Gasketech’s full face gaskets, you invest in quality and performance, ensuring maximum protection against leaks and contributing to the longevity of your equipment.

Optimized by: Netwizard SEO