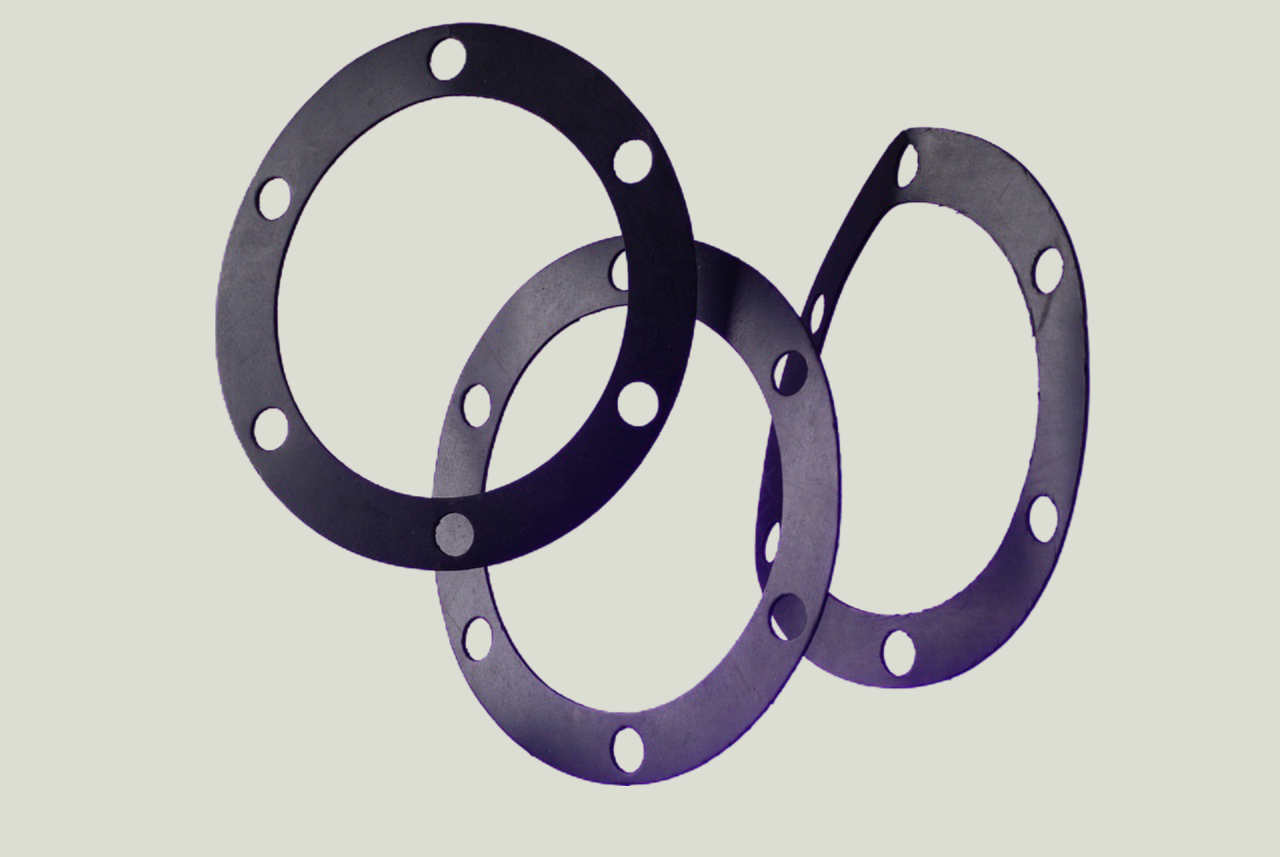

Customised Viton Gaskets for Oil & Chemicals: Superior Sealing for Extreme Conditions

07 April 2025

Customised Viton gaskets from Gasketech provide superior sealing solutions for oil and chemical applications, enhancing operational efficiency.

Why Customised Viton Gaskets Excel in Oil and Chemical Applications

Viton gaskets are renowned for their exceptional resistance to high temperatures, aggressive chemicals, and oils. Customisation allows these gaskets to be tailored to specific industry requirements, ensuring precise tolerance levels and compression resistance that meet the unique demands of each application.

Gaskets made of Viton resist high temperatures and compression set, providing good electrical properties for low-voltage applications. This capability ensures they maintain their integrity even in environments with fluctuating temperatures and pressures.

Boosting Efficiency with Customised Viton Gaskets

High-quality Viton gaskets significantly reduce maintenance needs and prevent costly downtime by providing a reliable seal that withstands extreme temperatures and chemical exposure. This results in enhanced efficiency of machinery and pipelines, as less time is spent on repairs and replacements.

Viton gaskets support a wide temperature range, from -9°C to 204°C, and can handle intermittent temperatures up to 260°C. They offer excellent resistance to:

• Oils

• Alkalis

• Concentrated bases

• Most mineral acids

• Sun, weather, and oxidation

• Mold and fungus

In addition to their exceptional solvent and oil resistance, Viton gaskets also exhibit outstanding resistance to abrasion and tear. Their low burning properties make them even more appropriate for uses where safety and longevity are crucial.

Industries That Rely on Customised Viton Gaskets

Various industries rely on personalised Viton gaskets for reliable sealing solutions. These gaskets are essential due to their ability to withstand challenging conditions.

1. Automotive Industry: Modified Viton gaskets are used in the automotive sector for sealing fuel systems and engines, ensuring durability and efficiency.

2. Aerospace Industry: Customised Viton gaskets are critical in aerospace for sealing systems that require high reliability and resistance to extreme temperatures and chemicals.

3. Oil & Gas Industry: The oil and gas industry relies on personalised Viton gaskets for sealing equipment that handles aggressive chemicals and high-pressure systems.

4. Chemical Processing Industry: Specialised Viton gaskets are essential in chemical processing for sealing equipment that handles corrosive substances and operates under high temperatures.

5. Industrial Manufacturing: These customised gaskets are used in industrial manufacturing to seal machinery that requires high durability and resistance to oils and chemicals.

6. Marine Industry: These gaskets are used in marine applications to withstand saltwater and extreme weather conditions.

7. Power Generation: Personalised Viton gaskets are used in power generation systems to ensure reliable sealing under high temperatures and pressures.

Gasketech’s Customised Viton Gaskets for Enhanced Efficiency

The effectiveness of modified Viton gaskets in oil and chemical applications underscores their value in maintaining operational efficiency. Gasketech offers a comprehensive range of customised gaskets tailored to meet industry needs, ensuring superior sealing performance and reliability in extreme conditions.

View our full selection of customised full face gaskets for superior sealing solutions.

Refer to Viton Gaskets from Interstate Specialty Products for the tool’s technical information.

Optimized by: Netwizard SEO