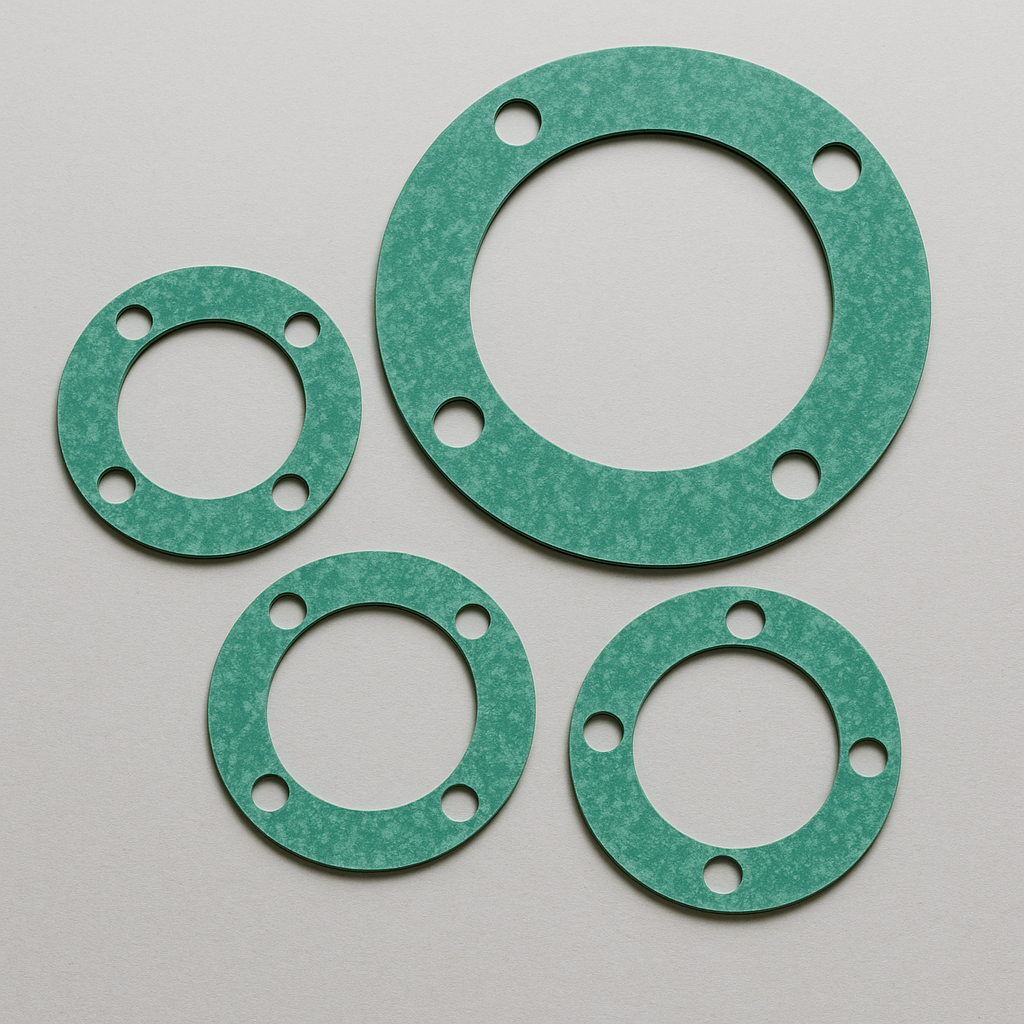

Compressed Non-Asbestos Fibre Gaskets: Graphite Sealing for Automotive Hot Oil System

07 May 2025

Choose Gasketech for quality compressed non-asbestos fibre gaskets with graphite sealing, ideal for automotive hot oil systems’ reliable performance.

Compressed non-asbestos fibre gaskets offer a reliable sealing solution for automotive hot oil systems, effectively preventing leaks and enhancing system performance. Their advanced composition, incorporating graphite, ensures a robust seal that withstands high temperatures and pressures in demanding automotive environments.

Role of Compressed Non-Asbestos Fibre Gaskets in Automotive Systems

In automotive hot oil systems, these gaskets secure crucial components, maintaining a leak-free environment under varying pressure and temperature conditions. Their design ensures optimal performance and contributes to the overall reliability of engine systems, especially in high-stress conditions.

Their effectiveness in preventing external contaminants from entering the system is crucial for maintaining the integrity of engine oil. Such prevention helps keep the system running smoothly and avoids potential damage to critical engine parts.

Benefits of Graphite Sealing in Hot Oil Systems

Graphite sealing in gaskets offers exceptional resistance to high temperatures, ensuring the gasket’s durability and maintaining its sealing function in hot oil systems. This temperature resilience is essential for keeping the engine protected, even during prolonged high-heat exposure.

The inclusion of graphite also enhances the gasket’s sealing integrity, providing a more effective barrier against leaks. This results in better system performance and reduces the likelihood of oil loss, which can affect engine efficiency and longevity.

Maintaining Gasket Performance in Automotive Applications

Regular maintenance of compressed non-asbestos fibre gaskets is essential to ensure they continue functioning effectively in automotive hot oil systems. Below are key practices to help preserve gasket performance and extend its lifespan.

• Regular Inspections: Periodically checking the gasket for wear or damage ensures that any potential issues are detected early, preventing further complications in the system.

• Correct Installation: Ensuring proper installation of the gasket prevents misalignment or compression issues that may lead to leaks or reduced sealing performance.

• Proper Torque Settings: Using the recommended torque settings during installation prevents over-tightening, which can cause gasket deformation or failure.

• Heat Monitoring: Monitoring the operating temperature helps to ensure the gasket is functioning within its specified temperature limits, reducing the risk of heat-related failures.

• Lubrication: Applying appropriate lubricants to the gasket during installation improves its sealing efficiency and prolongs its lifespan by reducing friction and wear.

• Timely Replacements: Replacing gaskets as soon as signs of wear are detected helps maintain system integrity and avoids compromising engine performance due to seal failure.

Reliable Gasket Solutions for Automotive Systems

Gasketech provides high-quality compressed non-asbestos fibre gaskets, incorporating graphite for superior sealing performance in automotive hot oil systems. Our gaskets ensure long-lasting protection and reliability in challenging environments.

Enquire with us for more information on our gasket solutions and other workshop material packs.

Related blog: Non-Asbestos Compressed Fibre Gaskets for Enhanced Industrial Sealing

Discover more technical details about the range of non-asbestos compressed fibre gaskets from PTM Limited.

Optimized by: Netwizard SEO