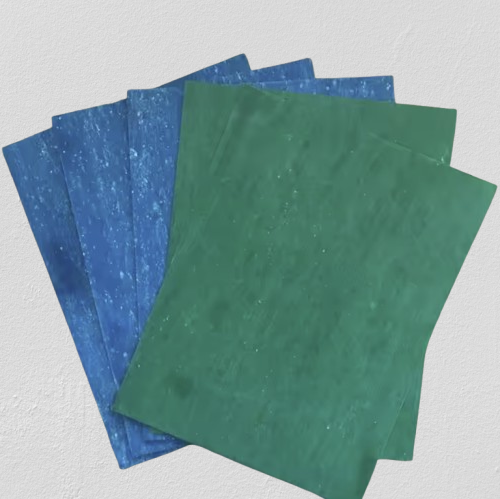

Oil Jointing Gasket Sheets for Water Pumps and Industrial Sealing Applications

04 July 2025

Source oil jointing gasket sheets from Gasketech in Melbourne, tailored for durable water pump and industrial machinery sealing solutions.

Material Composition of Oil Jointing Gasket Sheets

The formulation of oil jointing gasket pads relies on a precise blend of raw materials, each selected to maximise sealing capability and mechanical strength. Cellulose fibres form the structural foundation, providing flexibility and resilience under sustained compression. Rubber binders, along with reinforcing compounds, further enhance resistance to water, oil, and common industrial chemicals.

Chemical additives within the composition support temperature stability and prolong service life, reducing the likelihood of premature gasket failure. These engineered materials contribute to exceptional sealing properties, making these vegetable fibre gasket sheets a preferred option for both original equipment manufacturers and ongoing maintenance requirements.

Choose from Gasketech’s oil jointing gasket sheet range, offered in these sizes to meet various industrial needs:

• WP 11 – 1000 x 300 x 0.25 mm

• WP 12 – 1000 x 300 x 0.4 mm

• WP 13 – 1000 x 300 x 0.8 mm

Oil Jointing Gasket Sheets in Water Pump Maintenance

Oil jointing gasket sheets serve as a reliable sealing solution for water pumps, addressing frequent issues such as fluid leakage, joint misalignment, and gasket failure under pressure. Enhanced sealing performance maintains water pump efficiency, supporting stable operation and reducing repair intervals.

Key aspects in water pump maintenance include the following:

• Effective sealing of flanged pump joints

• Resistance to water and mild chemicals commonly present in pump systems

• Adaptability to irregular or worn flange surfaces

• Consistent pressure containment under varying operational loads

• Prolonged service intervals by reducing maintenance frequency

Performance Advantages of Oil Jointing Gasket Sheets for Industrial Sealing

Robust engineering sustains the industrial gasket paper, enabling stable sealing across varied industrial conditions. Thermal and pressure resistance meet stringent industrial standards, while compatibility with a wide range of chemicals ensures performance across multiple process types. Leak prevention is reinforced by consistent material density and resilience.

The following bullet points highlight unique performance features relevant to industrial use:

• Sustained sealing under thermal cycling: Maintains integrity despite frequent temperature changes.

• Stable performance under mechanical stress: Resists deformation under fluctuating load conditions.

• Reliable barrier against hydrocarbons and fluids: Prevents ingress and egress of fluids.

• Chemical compatibility with industrial media: Withstands exposure to oils, solvents, and coolants.

• Compression set resistance: Retains sealing thickness over repeated use.

• Adaptable thickness options: Customisable profiles suit various equipment and installation needs.

• Dimensional stability over extended periods: Preserves form, limiting gasket creep and compression loss.

Reliable Sealing Performance with Gasketech

As a trusted manufacturer and supplier, Gasketech offers oil jointing gasket sheets specifically designed for demanding water pump gaskets and a wide range of industrial sealing applications. Clients may also request customised oil jointing gasket solutions tailored to specific dimensions or performance specifications.

Review our workshop-ready gasket options designed to support a wide range of applications.

Optimized by: Netwizard SEO