CNAF Gaskets: How to Choose the Right One for Your Industrial Application

09 August 2024

Learn how to choose the right CNAF gaskets for your industrial application with Gasketech. Discover the key factors to consider for optimal sealing performance.

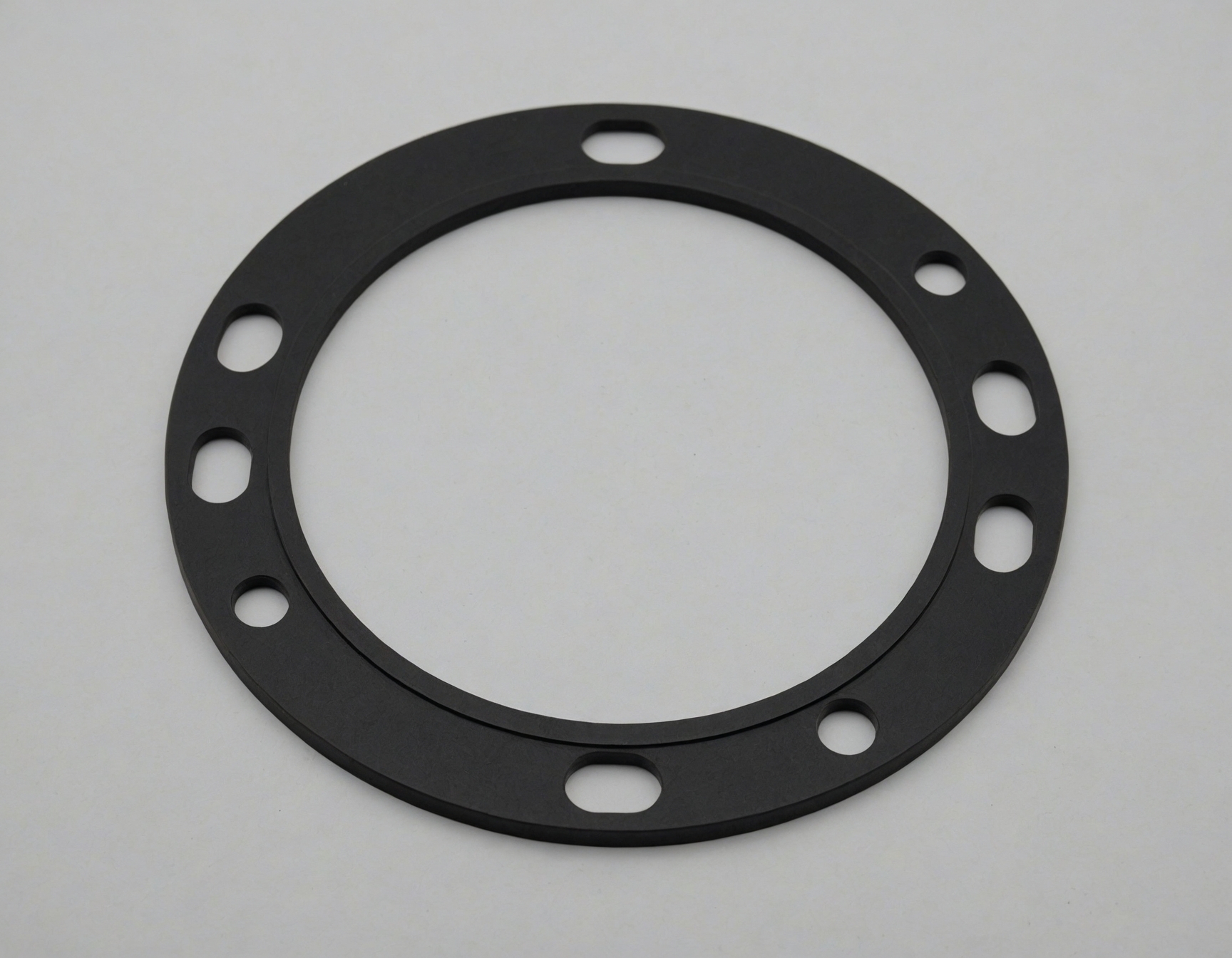

CNAF (Compressed Non-Asbestos Fibre) gaskets are a versatile and reliable choice for industrial sealing applications. These gaskets are made from a combination of materials, including aramid, cellulose, carbon, and synthetic rubber, making them suitable for a wide range of operating conditions. As a manufacturer and supplier of gaskets and sealing products, Gasketech understands the importance of selecting the right CNAF gasket for your specific industrial needs.

Types of CNAF Gaskets

CNAF gaskets are available in several grades, each designed to meet specific industrial requirements. Some common types include:

• Standard CNAF: Suitable for general-purpose applications with moderate temperature and pressure conditions.

• Oil-resistant CNAF: Engineered to withstand exposure to oils, fuels, and other petroleum-based products.

• High-temperature CNAF: Designed for applications involving elevated temperatures, typically up to 400°C.

• Acid-resistant CNAF: Formulated to resist corrosion from acids and other aggressive chemicals.

• Food-grade CNAF: Manufactured to comply with regulations for use in food and beverage processing industries.

Factors to Consider When Choosing CNAF Gaskets

When selecting the right CNAF gasket for your industrial application, consider the following factors:

Operating Conditions

Assess the temperature, pressure, and chemical exposure your gasket will face to ensure you choose a material that can withstand the environment. CNAF gaskets have a wide temperature range of -200°C to 400°C and can handle pressures up to 500 PSI (34.5 bar), making them suitable for a variety of harsh conditions. However, it’s crucial to select a grade that matches the specific operating parameters of your application.

Industry-Specific Requirements

Understand the specific standards and regulations that apply to your industry, such as WRAS approval for use with potable water. CNAF gaskets are commonly used in the chemical, automotive, food, pharmaceutical, and power and energy industries, each with its own set of requirements. Ensure the CNAF gasket you choose meets all necessary certifications and approvals for your industry.

Gasket Size and Shape

Ensure the CNAF gasket you choose can be easily cut or moulded to fit the specific dimensions of your application. CNAF gaskets are available in a variety of grades and formulations, allowing you to find a material that meets your unique requirements. Their flexibility also enables them to fill gaps and irregular surfaces, providing a tight seal even in complex applications.

Cost and Availability

Consider the cost of the CNAF gasket and its availability to ensure you can maintain a reliable supply for your operations. CNAF gaskets are generally more affordable than metal and some specialised rubber gaskets, offering a good balance of performance and cost. However, it’s essential to ensure that the CNAF gasket you choose is readily available from reputable suppliers to avoid disruptions in your production schedule.

Installation and Maintenance Tips

Proper installation and maintenance are crucial for the optimal performance of CNAF gaskets. Ensure proper alignment of flanges and clean mating surfaces before installation. Use appropriate torque values when tightening bolts to avoid over-compression. Then, regularly inspect gaskets for signs of wear, degradation, or leakage. Lastly, replace gaskets during scheduled maintenance to prevent unexpected failures.

Gasketech is here to help you navigate the world of CNAF gaskets. Remember, investing time in choosing the right CNAF gasket can improve operational efficiency in the long run.

Optimized by: Netwizard SEO