Unleash superior leak prevention with full face gaskets from Gasketech. Explore their benefits and applications for reliable sealing in industrial applications.

Reliable sealing from full face gaskets and others is essential for preventing leaks, contamination, and downtimes, which can only result in costly repairs and production losses. Full face gaskets are a significant component of industrial systems as they provide a secure and effective barrier against fluid and gas leakage in a wide range of applications.

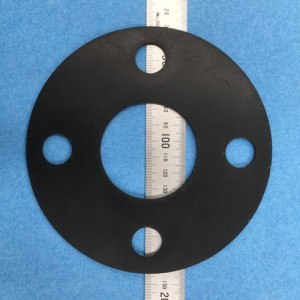

Full face gaskets are sealing devices designed to create a tight and leak-proof seal between two flat surfaces, such as flanges, pipes, or machinery components. Unlike ring gaskets that only cover the flange sealing surface, full face gaskets extend across the entire face of the flange, providing complete coverage and sealing protection. These gaskets are typically made from flexible materials such as rubber, silicone, PTFE (Teflon), or graphite, which are chosen based on the specific application requirements and operating conditions.

Currently, Gasketech offers full face gaskets to businesses requiring proper sealing protection for their respective industrial systems. Some notable applications of our full face gaskets include piping systems, pressure vessels, heat exchangers, pumps, compressors, and engines.

Full face gaskets offer several benefits for industrial sealing applications.

• Comprehensive Sealing: By covering the entire face of the flange, full face gaskets provide a complete and uniform seal, reducing leaks and ensuring reliable containment of fluids and gases.

• Enhanced Stability: Full face gaskets distribute sealing pressure evenly across the flange surface, which promotes stability and prevents distortion or damage to the sealing interface.

• Resistance to Compression Set: High-quality full face gaskets are engineered to resist compression set, maintaining their sealing integrity over extended periods of use and under varying pressures and temperatures.

• Cost-Effective: Aside from their superior sealing performance, full face gaskets are often cost-effective compared to alternative solutions, offering excellent value for money.

• Remarkable Versatility: Full face gaskets are available in a wide range of materials, sizes, and configurations to accommodate different flange designs, operating temperatures, and chemical compatibility requirements.

To maximise the effectiveness of full face gaskets, proper installation and maintenance practices must be done. Flange surfaces, for one, must be clean, flat, and free from defects or damage that could compromise the sealing integrity. Additionally, they should be installed with the correct torque and compression to achieve the desired level of sealing performance. Regular inspections and replacements of full face gaskets are then recommended to address wear, deterioration, or damage over time and maintain reliable sealing in industrial systems.

Full face gaskets from Gasketech can ensure superior leak prevention and reliable sealing in industrial settings. With their comprehensive coverage, stability, versatility, and cost-effectiveness, they offer an effective solution for sealing flanged connections, piping systems, and other critical components.

By unleashing the power of full face gaskets, your industrial facility can minimise the risk of leaks, contamination, and downtime, guaranteeing safe and efficient operation while maximising productivity and profitability. With proper installation, maintenance, and selection of high-quality gasket materials, your business can then achieve dependable sealing performance and peace of mind.

Explore the cost-effectiveness of Viton gaskets in harsh environments. Sold by Gasketech, learn how these durable seals offer long-term reliability and savings.

Industries, where equipment is exposed to extreme temperatures, chemicals, and pressure, can take advantage of Viton gaskets. Choosing the right gasket material for any industry is vital. For the past few years, Viton gaskets have emerged as a cost-effective solution for sealing applications in harsh environments. But before opting for these gaskets, you must first know their composition, their cost-effectiveness, and how they provide long-term reliability and savings for industrial operations.

Viton is a fluoroelastomer material known for its exceptional resistance to heat, chemicals, and environmental degradation. Gaskets made from this material are widely used in industries such as automotive, aerospace, chemical processing, and oil and gas as they require reliable sealing.

Some notable features of Viton gaskets are as follows.

• Superior Chemical Resistance: One of the key features of Viton gaskets is their resistance to a wide range of chemicals, including acids, fuels, solvents, and oils. Unlike other elastomeric materials, Viton maintains its integrity when exposed to harsh chemicals, reducing the risk of seal failure and costly equipment damage.

• High Temperature Stability: Viton gaskets exhibit excellent thermal stability, withstanding temperatures ranging from -15°C to 200°C and even higher in certain formulations. This makes them suitable for sealing applications in extreme temperature environments such as engines, exhaust systems, and industrial ovens.

• Long-Term Durability: Viton gaskets are renowned for their long-term durability and resistance to compression sets, guaranteeing reliable sealing performance over extended periods of use. Their ability to maintain a tight seal under varying operating conditions minimises the need for frequent gasket replacements, reducing maintenance costs and downtime in industrial equipment.

• Low Permeability: Viton gaskets exhibit low gas permeability, which makes them ideal for sealing applications that involve gas or fluid containment. This specific feature ensures the integrity of sealed systems, enhancing safety, compliance, and operational efficiency in industrial processes.

Viton gaskets are available at Gasketech. They are available in a variety of formulations and configurations to suit different sealing requirements and equipment specifications. Whether it’s static seals, dynamic seals, or custom-shaped gaskets, we can offer versatile Viton gaskets to meet a wide range of mating surfaces and sealing geometries.

Opting for Viton gaskets grants you a lot of advantages.

For one, the exceptional durability and long service life of Viton gaskets translate to reduced maintenance costs for industrial equipment. With fewer gasket replacements and less frequent downtime for maintenance, your business can realise significant savings in labour, materials, and lost productivity. Viton gaskets can also minimise the risk of equipment failure and unplanned downtime. Through their reliable sealing performance in harsh environments, these gaskets can help prevent costly repairs, equipment damage, and production delays.

Ultimately, using Viton gaskets improves overall productivity and efficiency in your industrial operation by ensuring consistent sealing performance and system reliability. With fewer disruptions due to seal failure or leakage, processes can run smoothly, and resources can be allocated more efficiently, maximising output and profitability.

The cost-effectiveness of Viton gaskets in harsh environments stems from their superior chemical resistance, high-temperature stability, long-term durability, and compatibility with a wide range of applications. By investing in Viton gaskets, your business can achieve huge savings in upkeep costs, reduce the risk of equipment failure, and enhance productivity and efficiency in industrial operations.