Unearth the qualities of oil jointing gasket sheets. Available at Gasketech, know how they make industrial sealing efficient and reliable. Call (03) 9690 2577.

Industrial operations often maximise intricate machinery and pipelines to ensure they are successful. One aspect of these things, however, that must be present is effective sealing. Choosing the right sealing materials plays a pivotal role in ensuring that chemicals, fluids, and gases are contained efficiently and safely while industrial processes are conducted. Among the various options available, oil jointing gasket sheets stand out as a versatile and high-performance solution, contributing to the enhancement of industrial sealing processes.

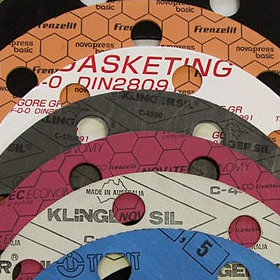

Oil jointing gasket sheets are engineered materials designed specifically for applications where resistance to oil, fuel, and other hydrocarbons is significant. Composed of materials such as aramid fibres, synthetic rubber, and other reinforcing elements, they exhibit exceptional sealing properties under challenging conditions. Generally, these sheets are known for their durability, resilience, and ability to maintain a reliable seal even in the presence of oils and fuels.

Available at Gasketech, oil jointing gasket sheets can easily boost industrial sealing applications as they boast the following notable features.

• Oil Resistance: The primary characteristic that sets oil jointing gasket sheets apart is their resistance to various oils and hydrocarbons. It makes them ideal for applications in industries such as automotive, petrochemical, and manufacturing where exposure to oils is common.

• Chemical Resistance: In addition to oil resistance, oil jointing gasket sheets often exhibit resistance to a variety of chemicals. This broad chemical compatibility enhances their suitability for diverse industrial environments.

• Temperature Tolerance: Oil jointing gasket sheets are likewise engineered to withstand a broad range of temperatures, making them suitable for applications where temperature fluctuations are prevalent. Using them ensures a stable and effective seal even in demanding thermal conditions.

• High Level of Compressibility: The compressibility of oil jointing gasket sheets allows them to conform to irregular surfaces, creating a tight and reliable seal. This feature is essential for preventing leaks and ensuring the integrity of industrial systems.

• Versatility: Oil jointing gasket sheets are available in various thicknesses and compositions, providing versatility in meeting the specific requirements of different sealing applications. This quality makes them a preferred choice in industries with diverse sealing needs.

All features of oil jointing gasket sheets make them useful in a lot of industries.

The automotive industry, for one, uses oil jointing gasket sheets to seal engine components, transmission systems, and fluid-carrying parts. The manufacturing industry also uses these sealing materials to ensure leak-free operations in equipment and machinery. Even the petrochemical industry utilises them to seal connections in pipelines, valves and pumps that handle oil and gas. The marine industry, lastly, uses them to seal joints and connections in marine engines and equipment.

With our professional help at Gasketech, you can select the right oil jointing gasket sheets for your applications. You can go for the right sealing solutions as long as you consider the type of fluid or gas being sealed, operating temperatures, pressure conditions, and specific industry requirements. We can also provide you with a range of options to address the diverse needs of your industrial applications.

Optimise your water supply systems with the right gasket supply from Gasketech. Invest in the correct gasket materials for these systems. Call (03) 9690 2577.

Water supply systems are networks of infrastructure meant to provide a consistent and safe water supply to buildings. They ensure the availability of clean and potable water for drinking, sanitation, industrial processes, and more. These systems include treatment facilities, distribution networks, storage reservoirs, and natural water sources.

The Significance of Using the Right Gaskets

To make these systems work, they must be fitted with the right components. One of these components is the gaskets. Gaskets serve as essential components that create a tight and secure seal between various elements in pipelines, valves, and other water infrastructure.

Now, selecting the right gasket is crucial to prevent leaks, maintain water quality, and enhance the overall efficiency of water supply systems. One factor that must be considered when picking the gaskets for these systems is the material.

Gasket Materials for Water Supply Networks

To date, here are some of the top gasket materials that are instrumental in ensuring the integrity of water supply networks.

• Rubber: Rubber gaskets, particularly those made EPDM (ethylene propylene diene monomer), are widely used in water supply systems. EPDM rubber is known for its excellent resistance to water, ozone, and weathering, making it suitable for outdoor applications.

• PTFE (Polytetrafluoroethylene): PTFE gaskets, commonly known by the brand name Teflon, are known for their exceptional chemical resistance and low friction properties. In water supply systems where exposure to aggressive chemicals is a concern, these gaskets provide reliable sealing without compromising on performance. Their resistance to temperature extremes adds to their suitability for diverse water infrastructure applications.

• Graphite: Graphite gaskets are known for their excellent heat resistance and sealing capabilities. In water supply systems that involve high temperatures, such as in industrial processes or hot water distribution, graphite gaskets provide a reliable solution. They also exhibit good chemical resistance, ensuring long-lasting performance in challenging environments

• Compressed Non-Asbestos: Compressed non-asbestos gaskets are engineered to provide a safer alternative to traditional asbestos gaskets. These gaskets are composed of a combination of fibres, fillers, and elastomers. They offer good sealing properties and are widely used in water supply systems where the avoidance of asbestos is a priority. These gaskets are suitable for a range of water applications, including potable water systems.

All these gasket materials can be purchased from us at Gasketech.

Choosing the Best Gasket for Your Systems

When choosing the right material for your water supply system, you must consider several factors.

First, you must know the temperature conditions in your water supply system. You must pick gasket materials that can withstand temperature variations in your system without compromising their sealing effectiveness. You must also consider the chemicals present in the water. Your gasket material must be compatible with the specific chemical composition of the water to ensure longevity and reliability.

Even the pressure requirements of your system must be considered so you can opt for gasket materials that can withstand them without causing leaks. Ultimately, you must consider the environmental conditions of your water supply systems. Your system may be exposed to UV radiation and weathering, which can only work effectively when paired with gasket materials that can withstand them.