Gasketech is your trusted gasket supplier. Supporting maintenance engineers with reliable solutions. Choose quality and dependability. Call (03) 9690 2577.

Gaskets are components that can be installed in industrial equipment and systems. Once installed, they can act as a barrier between mating surfaces, preventing leaks and maintaining the integrity of the system. Given the importance of gaskets, maintenance engineers should always have access to these components from a trusted supplier.

Key Responsibilities of Maintenance Engineers

Various industries rely on maintenance engineers to carry out the following:

• Preventive Maintenance: Maintenance engineers implement preventive maintenance programs to minimise the risk of equipment failure and unplanned downtime. They conduct routine inspections, perform scheduled maintenance tasks, and identify potential issues before they escalate into major problems.

• Equipment Troubleshooting and Repairs: When equipment malfunctions or breaks down, maintenance engineers identify the root cause of the problem and conduct necessary repairs. They use their technical expertise and problem-solving skills to diagnose issues, replace faulty components, and restore equipment functionality.

• Equipment Calibration and Testing: Maintenance engineers are also responsible for calibrating and testing equipment to ensure accurate measurements, performance, and compliance with industry standards. They use specialised tools and instruments to verify the accuracy of sensors, gauges, and control systems.

• Maintenance Planning and Scheduling: Maintenance engineers develop maintenance plans and schedules based on equipment requirements, operational needs, and production demands. They prioritise tasks, allocate resources effectively, and coordinate maintenance activities to reduce disruptions to production processes.

• Documentation and Reporting: Ultimately, maintenance engineers maintain accurate records of maintenance activities. These records include inspection reports, repair logs, and equipment history. They generate comprehensive reports to track equipment performance, identify maintenance trends, and ensure compliance with regulatory requirements.

How Maintenance Engineers Maximise Gaskets

The vast responsibilities of maintenance engineers require them to maximise the right tools and equipment for their jobs. Additionally, they should invest in the right gaskets and other components to ensure proper servicing of industrial equipment and systems.

After all, access to quality gaskets allows these professionals to maintain a tight seal between mating surfaces in equipment and systems. Once installed, they can expect these things to be protected from leaks and system integrity issues, minimising the risk of equipment failure and costly downtime. Maintenance engineers also maximise quality gaskets to effectively optimise the performance of equipment and systems. With the right gaskets, the mating surfaces will be sealed tightly, minimising the loss of fluids, energy, or pressure.

Maintenance engineers likewise use gaskets to ensure the safety of personnel and protect the environment. A reliable seal prevents the release of hazardous substances like chemicals or gases in the environment. It can also minimise the risk of accidents or incidents due to leaks.

Choose Gasketech as Your Reputable Supplier

If you want to gain access to quality gaskets, you must choose us at Gasketech.

At Gasketech, we prioritise quality and reliability in our products. We provide gaskets designed to withstand high temperatures, pressures, and corrosive environments as quickly as possible. We also maximise a wide range of materials to design and manufacture gaskets. Our team can even customise the gaskets to meet the requirements of your respective projects without compromising their reliability and compliance with standards.

Lastly, we provide technical support and expertise to address any sealing issues and make informed decisions regarding gasket materials, sizes, and installation techniques.

Meet the unique requirements of specific sealing applications through custom gaskets. Work with Gasketech to know how we generate your needed sealing items.

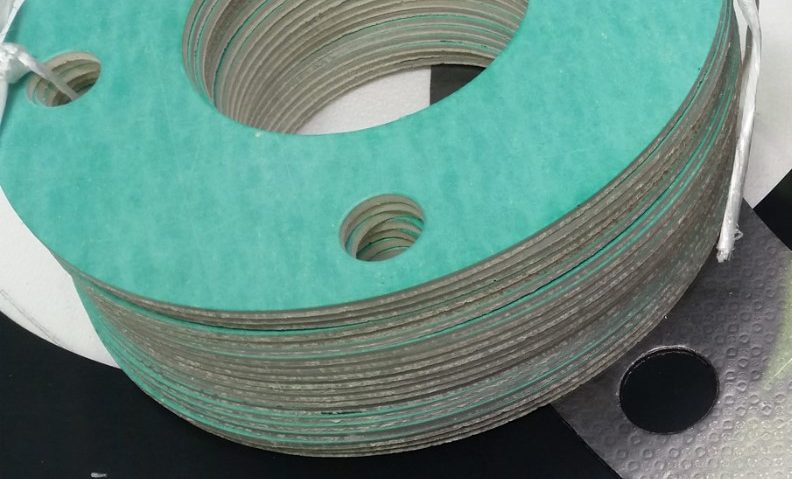

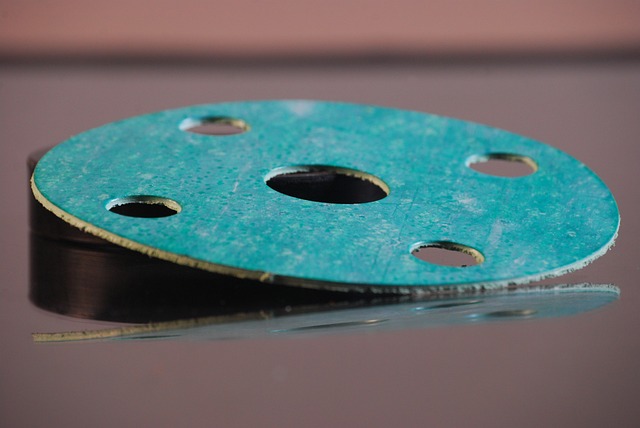

Custom gaskets are sealing solutions specifically designed, manufactured, and sold to meet the unique requirements of specific applications. Unlike standard, off-the-shelf gaskets, custom gaskets are not mass-produced. They are, instead, tailored to fit specific sealing surfaces, accommodate irregular shapes, and address unique environmental or operational challenges.

At Gasketech, we know the significance of matching the gaskets to your intended applications. Hence, we approach everything proactively to ensure you can maximise gaskets and even other sealing materials for your specific needs. We pick the right processes and materials to produce the gaskets that truly match your requirements.

The Process of Creating Custom Gaskets

The effectiveness of custom gaskets can only be achieved by industries if they are designed and planned properly. Normally, a collaboration between the gasket manufacturer and the customer is necessary for creating custom gaskets. The manufacturer must work closely with the customer to understand the application’s needs, which include the desired performance characteristics and any specific industry regulations or standards that should be met.

Now, one aspect of custom gaskets that make them different from the standard ones is their material. Some may be made from rubber, while others can be produced out of specialised polymers. Materials maximised for producing custom gaskets may differ based on temperature, pressure, chemical compatibility, and environmental conditions in which they will be utilised. These things can only be recognised once the manufacturer collaborates with the customer.

Other aspects that should be considered in making custom gaskets include the grooves, ridges, and specialised profiles. Knowing these things can help manufacturers create gaskets that accommodate unique sealing surfaces and fit the constraints of the applications.

Outstanding Benefits of Custom Gaskets

With Gasketech, you are assured of gaskets that can truly fit your needs and requirements. As we consider all the previously stated aspects and factors, our custom gasket can conveniently provide the following benefits.

• Precise Fit: Custom gaskets are tailored to fit specific sealing surfaces, which ensures a precise and secure fit. This benefit eliminates the risk of leaks and inefficiencies. The precise fit also helps optimise the performance of your sealing system.

• Enhanced Performance: Custom gaskets can easily meet the unique demands of an application, taking into account factors such as temperature, pressure, chemical compatibility, and environmental conditions. Their enhanced performance ensures they provide an effective and reliable seal, even in challenging operating conditions.

• Improved Durability: Custom gaskets are designed with the specific application in mind, taking factors like wear and tear, exposure to harsh environments, and the expected lifespan of the equipment. By selecting the correct materials and configurations, they can offer enhanced durability, which results in longer-lasting seals and reduced downtime.

• Ensured Compatibility: Unlike off-the-shelf gaskets, which may require modifications or compromise the seal’s effectiveness, custom gaskets are precisely engineered to accommodate unique sealing surfaces. Therefore, they can easily fit irregular shapes, non-standard sizes, and complex geometries.

• Cost-Effectiveness: While custom gaskets may have a higher initial cost compared to off-the-shelf gaskets, they often prove to be more cost-effective in the long run. These gaskets can meet specific requirements, which minimises the risk of seal failure and the need for frequent replacements. This benefit results in cost savings by reducing downtime, decreasing maintenance costs, and improving operational efficiency.

Custom gaskets for specific requirements offer a precise fit, enhanced sealing performance, compatibility with irregular shapes and sizes, improved durability and longevity, cost-effectiveness, and many more. As long as you work with us at Gasketech, you can easily secure custom gaskets that boast these outstanding benefits.