Uncover the precision and reliability of vulcanised fibre gaskets from Gasketech. Ensure effective and precise sealing. Call us at (03) 9690 2577 today!

Industrial plants and other similar businesses rely heavily on a variety of tools, equipment pieces, and others to ensure they operate seamlessly. Now, two things they require to achieve a successful daily operation are precision and reliability. To achieve these things, they must only maximise high-quality solutions. Sealing, for instance, must be done with the use of the right gaskets.

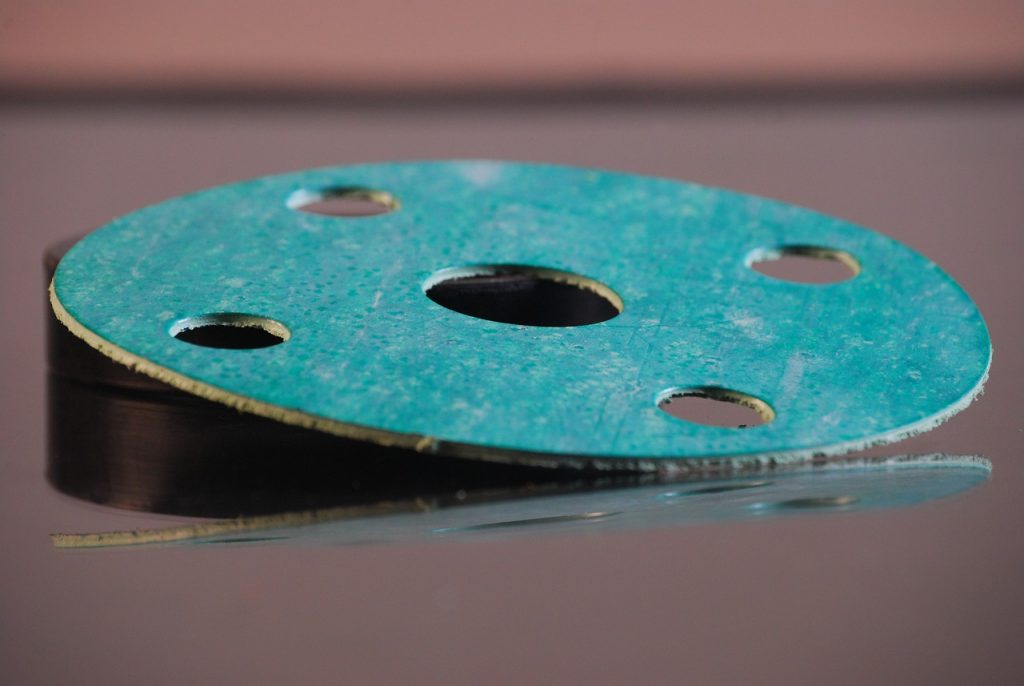

Many types of gaskets can be utilised by different industries today. However, one type that stands out the most is the vulcanised fibre gasket. Vulcanised fibre gaskets have emerged as a dependable choice for preventing leaks, providing protection against elements, and maintaining airtight conditions.

The Benefits of Vulcanised Fibre Gaskets

At Gasketech, we offer vulcanised fibre gaskets to effectively meet the sealing demands of various industries and applications. Our vulcanised fibre gaskets boast the following benefits.

• Superb Sealing: Vulcanised fibre gaskets offer superior sealing properties, making them ideal for applications where leaks or ingress of contaminants are concerns.

• Precise Specifications: Vulcanised fibre gaskets are also known for their precision in manufacturing, ensuring they meet tight tolerances and exact specifications.

• Chemical Resistance: Vulcanised fibre gaskets demonstrate resistance to a wide range of chemicals, which makes them suitable for use in diverse environments.

• High-Temperature Tolerance: Vulcanised fibre gaskets can even withstand high temperatures without compromising their sealing integrity, making them dependable in extreme conditions.

• Compression and Resilience: Vulcanised fibre gaskets have excellent compression and resilience properties, allowing them to adapt to varying pressures and maintain their sealing capacity.

Vulcanised Fibre Gaskets from Gasketech

When you opt for vulcanised fibre gaskets from Gasketech, you can expect them to be aligned with the demands of your project since we only utilise the right materials in producing them. We even ensure your gaskets are compatible with the materials they will be in contact with to avoid any issues. We can also design and customise them according to the requirements of your project, making sure they can fit unique shapes and sizes as well as their surrounding conditions. The quality of our gaskets is likewise checked thoroughly to ensure they meet your specifications and last for a long time.

Applications of Vulcanised Fibre Gaskets

Vulcanised fibre gaskets can be maximised in a variety of applications.

The automotive industry, for instance, can use these gaskets in automotive engines, transmissions, and exhaust systems to ensure airtight and leak-free connections. Vulcanised fibre gaskets can also provide precision sealing in aircraft engines and critical systems where safety and reliability are paramount. Vulcanised fibre gaskets can then be used in electrical enclosures to maintain integrity against dust, moisture, and contaminants. Other places where vulcanised fibre gaskets can be installed are chemical reactors, pumps, valves, HVAC systems, wellhead equipment, and pipelines.

Vulcanised fibre gaskets from Gasketech are the embodiment of precision and reliability in sealing solutions. Their versatility and durability make them an excellent choice for applications across various industries, where ensuring precision sealing is highly important.

Uncover the advantages of customised felt gaskets by Gasketech in industrial applications. Learn how they enhance sealing, insulation, and more. Call 03 9690 2577.

Industrial applications maximise a variety of hardware components to effectively carry out a variety of processes. One of these components is the gaskets. Gaskets in general are hardware components meant to fill the gap or space between two or more mating surfaces, making sure any leakage from or into the joined objects will be prevented.

In producing gaskets, manufacturers can utilise different materials. One of these materials is felt. Felt gaskets have emerged as indispensable components that play a vital role in ensuring equipment and machinery operate seamlessly. Custom ones, which are available at Gasketech, offer numerous benefits in industrial applications. Some of them are as follows.

Ensured Precision

One of the standout benefits of customised felt gaskets lies in their tailor-made nature. Unlike off-the-shelf gaskets, these custom solutions are designed to exact specifications, ensuring a perfect fit for your equipment, machinery, or system. Their precision minimises the risk of leaks, vibrations, and inefficiencies that only contribute to optimal performance and longevity.

Minimised Modifications

Customised felt gaskets are typically manufactured using advanced cutting and machining techniques. Computer Numerical Control or CNC equipment ensures precise cuts and intricate designs, resulting in gaskets that perfectly match the intended application. This precision minimises the need for adjustments or replacements, which saves both time and resources. They can even be produced to meet specific thickness and density requirements, allowing engineers to fine-tune performance characteristics for different applications.

Versatile Applications

Customised felt gaskets find applications across diverse industries, from manufacturing and automotive to aerospace and electronics, due to their versatility. Felt gaskets excel at sealing applications, preventing the leakage of gases, liquids, and contaminants. Whether you are dealing with high temperatures, corrosive substances, or challenging environments, these gaskets offer dependable sealing solutions.

Felt gaskets also provide effective thermal insulation, making them invaluable in industries where temperature control is critical. They help maintain stable operating conditions, protect sensitive components, and reduce energy consumption. Alternatively, the cushioning properties of felt gaskets make them ideal for reducing noise and vibration in machinery and equipment, enhancing workplace safety but also extending the lifespan of mechanical components.

Boosted Cost-Effectiveness

While customised felt gaskets may have a higher initial cost compared to generic alternatives, their long-term benefits far outweigh the investment. By reducing downtime, enhancing equipment longevity, and improving overall efficiency, they offer a cost-effective solution that boosts industrial productivity.

Increased Sustainability

In an era of increasing environmental awareness, customised felt gaskets can also be designed with sustainability in mind. Using eco-friendly materials and processes, manufacturers can create gaskets that align with a company’s commitment to environmental responsibility.

Customised felt gaskets from Gasketech provide tailored solutions that enhance sealing, insulation, and more. Their precision manufacturing, versatility, and cost-effective advantages make them invaluable components across various industries. Whether you are seeking to optimise equipment performance, reduce maintenance costs, or improve environmental sustainability, customised felt gaskets offer a versatile and reliable solution for your industrial needs.

Uncover the characteristics of polyurethane gaskets by Gasketech. Explore their primary applications in various industries in Australia. Call (03) 9690 2577.

Gaskets play a crucial role in sealing and protecting components in a wide range of industries. Among the materials used for gaskets, polyurethane stands out for its versatility and performance. At Gasketech, we supply high-quality polyurethane gaskets to a variety of industries, making sure they maximise the right sealing components for their applications.

Main Characteristics of Polyurethane Gaskets

Polyurethane is a synthetic polymer known for its versatility, durability, and resilience. Once used for gaskets, it can easily create a secure and often airtight seal between two surfaces, preventing the leakage of fluids, gases, or contaminants. Polyurethane gaskets can also protect sensitive components.

These gaskets are favoured in many industries due to their unique characteristics.

For one, polyurethane gaskets can resist many chemicals, oils, and solvents, making them suitable for applications where exposure to harsh substances is common. They can also withstand wear and abrasion, which makes them ideal for sealing applications in machinery and equipment subjected to friction and movement.

These gaskets likewise have a wide temperature tolerance range, with some formulations capable of handling extreme cold or high-temperature environments. Other qualities of polyurethane gaskets include tear resistance, water and moisture resistance, and impact resistance.

Ultimately, polyurethane gaskets can maintain their sealing properties even when compressed or subjected to varying pressures, thanks to their flexibility.

Polyurethane Gaskets: Primary Applications

Polyurethane gaskets come in various shapes and sizes, including O-rings, flat gaskets, custom-moulded gaskets, and more. Their versatility and ability to adapt to specific requirements make them valuable in the following industries.

1. Automotive: Polyurethane gaskets are extensively used in the automotive sector for sealing engine components, transmissions, and exhaust systems. They offer excellent resistance to oil, fuel, and high temperatures, ensuring reliable performance in demanding conditions.

2. Manufacturing: In manufacturing, precision and durability are paramount. Polyurethane gaskets provide tight seals in machinery, preventing leaks and contamination. They are often used in hydraulic systems, pneumatic equipment, and heavy machinery.

3. Aerospace and Defence: In aerospace and defence applications, where reliability is critical, polyurethane gaskets are chosen for their resistance to extreme temperatures and harsh chemicals. They are used in aircraft components, missile systems, and more.

4. Marine and Offshore: The marine and offshore industries rely on gaskets to prevent water ingress and protect sensitive equipment. Polyurethane gaskets excel in maritime applications, resisting saltwater corrosion and maintaining sealing integrity.

5. Electronics and Electrical: Polyurethane gaskets play a vital role in protecting electronic and electrical components from dust, moisture, and contaminants. They are used in control panels, electrical enclosures, and sensitive electronic devices.

7. Food and Beverage Processing: Polyurethane gaskets are safe for use in food and beverage processing equipment. They resist chemicals, temperature variations, and abrasion, making them ideal for sealing in this industry.

8. Construction and Building: Polyurethane gaskets are used in construction and building applications for sealing windows, doors, and HVAC systems. They contribute to energy efficiency by preventing drafts and leaks.

Polyurethane gaskets, which are available at Gasketech, are versatile and find applications across a wide spectrum of industries. Their resistance to chemicals, temperature extremes, and wear, along with their ability to maintain tight seals, make them indispensable components in ensuring the reliability and functionality of various products and systems.

Unlock the world of high-temperature applications with graphite/Kevlar composite gaskets. Available at Gasketech, uncover their uses. Call us at (03) 9690 2577.

The quest for materials that can withstand extreme temperatures continues today. Fortunately, industrial engineering has evolved significantly over the past few decades, leading to substantial improvements in the processing of raw materials into useful products. Graphite/Kevlar composite gaskets, for instance, have emerged as versatile solutions for high-temperature applications, showcasing their resilience and adaptability in the face of challenging environments.

The Composition of Graphite/Kevlar Composite Gaskets

Graphite/Kevlar composite gaskets are specialised sealing materials engineered by mixing two distinct components: flexible graphite sheets and Kevlar fibres. This innovative combination generates a material that capitalises on the unique thermal and mechanical properties of both graphite and Kevlar.

Graphite, which is known for its exceptional heat resistance and ability to withstand high temperatures, provides thermal stability to the composite. This quality makes the material an ideal choice for applications where sealing under extreme heat is necessary. On the other hand, Kevlar is renowned for its remarkable strength and durability. Kevlar fibres enhance the mechanical integrity of the composite gaskets, reinforcing pressure, tension, and stress.

When these materials are combined, the resulting composite gaskets attain the heat-resistant qualities of graphite and the robust strength of Kevlar fibres. This mixture makes them highly effective in applications involving elevated temperatures and demanding sealing conditions.

Graphite/Kevlar Composite Gaskets Major Advantages

The general composition of graphite/Kevlar composite gaskets allows them to boast a variety of advantages for different industries. Some of their advantages are as follows.

• Improved Thermal Stability: The composite’s graphite component allows gaskets to withstand temperatures beyond the capabilities of traditional gasket materials.

• Boosted Sealing Performance: Graphite’s inherent flexibility likewise allows gaskets to conform to irregular surfaces, ensuring reliable and consistent sealing.

• Ensured Chemical Resistance: The combination of Kevlar fibres and graphite imparts resistance to corrosive chemicals and harsh environments.

• Increased Mechanical Strength: Kevlar reinforcement enhances the material’s mechanical strength, which reduces the risk of gasket failure under pressure.

• Reduced Emissions: Effective sealing in high-temperature applications contributes to reduced emissions by preventing leaks that can compromise system efficiency.

Graphite/Kevlar Composite Gaskets: Uses and the Future

All the advantages of graphite/Kevlar composite gaskets make them useful in many applications.

The automotive industry, for one, uses these gaskets to ensure a tight seal in exhaust systems, preventing them from leaking and enhancing their efficiency. The aerospace sector can also use these gaskets to maintain the integrity of aerospace engines and propulsion systems, which often operate under thermal stress. Even petrochemical plants can utilise graphite/Kevlar composite gaskets to provide thermal resistance and chemical resilience to refineries and chemical processing units.

Graphite/Kevlar composite gaskets can likewise be installed on gas turbines, boilers, and heat exchangers to ensure leak-free connections. Foundries and metalworking industries can also use these gaskets in moulds and joints to withstand the extreme heat of molten metals.

Novel high-temperature applications can then use these gaskets as advanced sealing solutions in a variety of emerging technologies. Ultimately, the nuclear sector can utilise these gaskets to withstand extreme conditions in reactor systems. Graphite/Kevlar composite gaskets, which can be acquired from us at Gasketech, have revolutionised high-temperature applications across diverse industries. Their ability to withstand extreme heat and provide excellent sealing positions them as indispensable components in critical systems.

Know the role of gasket material selection in chemical and petrochemical pipelines. Partner with Gasketech to pick the right materials. Call (03) 9690 2577.

Chemical and petrochemical industries rely heavily on the integrity and safety of pipelines to effectively optimise their day-to-day operations. One crucial yet often overlooked component that plays a vital role in ensuring the reliability of their pipelines is the gasket. Gaskets generally act as a seal between pipe flanges, which can help prevent leaks, contain hazardous substances, and maintain operational efficiency.

However, not all gaskets are created equal, especially when it comes to handling the corrosive and harsh conditions of chemical and petrochemical processes.

The Essence of Gasket Material Selection

In the chemical and petrochemical sectors, pipelines transport a wide array of aggressive chemicals, corrosive substances, and volatile fluids. Gaskets must effectively seal joints under high pressure and temperature while resisting the detrimental effects of chemical exposure and mechanical stress. Choosing the appropriate gasket material is crucial to prevent leaks, minimise downtime, and ensure the safety of personnel and the environment.

But selecting the right gasket material for chemical and petrochemical pipelines can be complex due to the diverse range of fluids being transported and the extreme conditions they encounter. Factors such as chemical compatibility, temperature variations, pressure fluctuations, and potential vibrations all play a part in determining the suitability of gasket materials. The challenge lies in identifying materials that can withstand these conditions without degrading significantly or compromising the integrity of a pipeline.

Key Material Options for Pipeline Gaskets

Several gasket materials can be specifically engineered to meet the demands of chemical and petrochemical pipelines. These materials include the following.

• Fluoroelastomers (FKM/Viton): Known for their exceptional chemical resistance, fluoroelastomers are often used for sealing applications that involve aggressive chemicals and high temperatures.

• Expanded PTFE (ePTFE): With its excellent chemical resistance and malleability, ePTFE gaskets can conform to uneven surfaces, which ensures effective sealing in challenging pipeline environments.

• Graphite: Graphite gaskets excel in high-temperature and high-pressure applications. They provide reliable sealing and can handle thermal cycling without losing their integrity.

• Spiral Wound: Comprising a combination of metal and filler materials, spiral wound gaskets offer versatility and resilience against extreme conditions, which makes them suitable for chemical and petrochemical pipelines.

Benefits of Proper Gasket Material Selection

Tons of benefits can be obtained when selecting gasket materials properly.

First, it can enhance the safety of chemical and petrochemical pipelines. The right gasket materials can ensure leak-free connections, preventing hazardous substances from escaping and minimising the risk of accidents. Proper gasket material selection can also ensure operational reliability. This process reduces the likelihood of unplanned downtime due to leaks, which contributes to the consistent operation of chemical and petrochemical processes.

Ultimately, investing in high-quality gasket materials that can withstand the harsh conditions of chemical and petrochemical pipelines can lead to long-term cost savings as they can minimise maintenance and replacement needs.

Gasket material selection is a critical factor in ensuring the integrity, safety, and performance of chemical and petrochemical pipelines. With the wide variety of materials available, understanding the specific demands of the application is essential for making informed decisions. By choosing gasket materials that are compatible with the transported fluids, industries can benefit from efficient, reliable, and safe pipeline operations in chemical and petrochemical facilities for a long time.