Regular geometrical shapes dictate conventional gasket design. We see them fabricated as circular and ovoid seals, the strong rubberized inserts that complete the meeting of two regular surfaces. Of course, there are situations where such sealing strategies fall short. These specialised applications call for made-to-measure solutions, which is where customised gaskets enter the project as tailor-made seals.

Unique Designs for Customised Gaskets

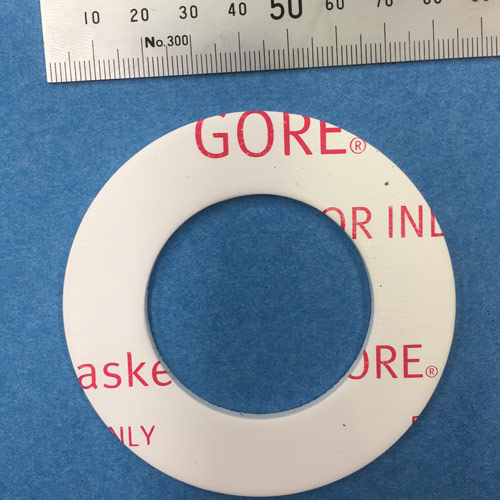

Imbued with custom-fit features, one-off gaskets are hand cut and laser cut, die stamped and water-jet shaped, all so that a customer can receive a seal that precisely integrates within the geometrical outlines of an irregularly configured joint surface.

Material Selection as a Science

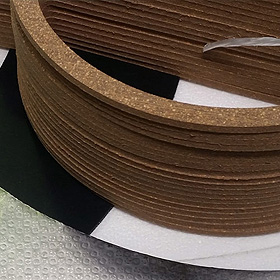

Versatile engineering departments are well-versed in the craft of selecting the right synthetic seal for a specific application. What’s required is knowledge of the transported fluid and all environmental conditions within and around the joint. Heat and pressure are two common issues here, but a custom solution reinforces the stressed component. Specifically manufactured seals add tailored material attributes to uncommonly overextended settings.

Common Dimensional Attributes Begin Here

Customers can relay shape requirements when they vary beyond normal constraints. After all, a circular form is easy to customise because a cutting tool can be quickly programmed to account for diameter changes, but this approach won’t work with complex geometrical outlines. One solution is to make a scaled drawing of the uncommon shape when submitting the project. CAD drawing software also works, as bolt holes and arcing shapes can easily be added into an irregularly described gasket when computer software is employed.

Evaluating Uncommon Requirements

If the shape of a gasket is as fluid as the medium being transported through a specific joint, then there may be other unique requirements. Rubberized seals are the standard material, one that varies finitely to accommodate environmental conditions, but there are also metal variants, plus a whole catalogue of flange face sealing aids. Perhaps the seal needs to deliver non-magnetic characteristics, or there’s a need for a compressible material, then that same soft seal may need to be reinforced with a special non-magnetic mesh, all the better to equip the gasket with composite toughness.

When talking about customised gaskets, the shape of the seal and the joint surface is the first variable we entertain. It’s a consideration that effects workshop tooling, obviously, but fabrication methods must also be assessed. We accommodate these design goals by partnering shape with material properties, thus creating a design strategy that offers full-package customization.

When sophisticated electronic modules are housed in dry control rooms, we know the gear is safe. Of course, sensitive circuits do exist outside of this refuge. It’s this scenario that causes our designers concern, for microchips can’t abide harsh environments. Thankfully, we can reinforce plainly fastened electronic’s housings with rubber gasket seals in electronic assemblies. Here’s how this is done.

Rubber Gasket Seals in Electronic Assemblies

If a box full of electronic circuitry is to be mounted in an environmentally challenging locale, a standardized enclosure won’t work. Even if we’re just referring to a regular outdoor setting, rainwater would eventually work its way into the box and destroy the microcircuitry. Instead, we use a rugged enclosure and outfit it with strong rubber gaskets. The lid is sealed with this gasket, as are the egress points where the wiring enters the box.

The Sealing of Submerged Electronics

The next wet environment is far more challenging. Imagine a pump or sensor package located down a deep well. The digital innards inside the pump measure the depth of the water. Meanwhile, the sensors conduct a test on the chemical components suspended in that water. Other electronic devices sink below the water line to work on marine vessels. Submerged as these housings are, they need to be rated to handle water pressure and turbulence. Temperature changes may be part of this environment, which would certainly be the case in a steamy boiler room, so the seals also need to compress without experiencing the expansion/contraction effects we associate with certain polymers.

The science of Ingress Protection

Electronic assemblies use these special enclosures to guarantee dry operability. The tiny currents running through the fine tracks work in concert with microprocessors and digital processing subsystems to monitor tiny changes within massive mechanical assemblies. The IP rating ensures these circuits are fully segregated from the chaos that’s going on outside. Please refer to this resource for more information on the critically important international IP Rating standard. Basically, the first number describes dust protection, while the second digit relates to liquids. Scaling from 1-through-8, an IP88 rating would be fully dustproof and waterproof, thus ready for installation in an abrasive quarry or a submerged environment.

The polymers used in these applications must conform to the housing, the access panel, and any gaps where wiring is to be routed. Additionally, rubber gasket seals in electronic assemblies must be fabricated so that they compress uniformly without giving into moisture, temperature extremes, or harmful chemicals.