Most engineering labels submit to a little common sense. We can even take shortcuts by splitting the term up and tackling each word, one at a time. That’s not going to work here, unfortunately, so let’s get to the meat of the matter and skip the preamble; gasket material traceability isn’t a phrase that will easily divulge its secrets to this simple shortcut, not unless we have a ready-to-submit description.

What is Gasket Material Traceability?

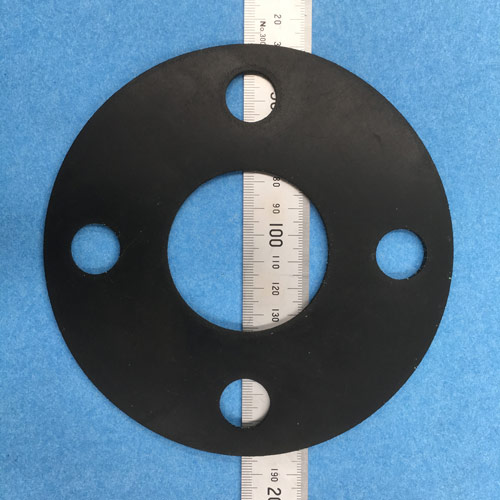

First of all, before attempting to solve a terminological puzzle, we should take this opportunity to emphasize the essential functions of a gasket. Pipes carrying pressurized steam are only as strong as the material inserted between flange surfaces, for instance. Similarly, the same principle applies to automotive systems and larger vehicles, to high-pressure mechanical power transmission assemblies and other scenarios where these mechanical seals are absolutely required. A traceability feature, one added to a gasket, provides material reinforcement, but it’s a virtual form of reinforcement. The code or documentation associated with the seal acts as a biography, one that forms a thread-like bond all the way back to the manufacturing plant where the component was initially fabricated.

Traceability as a Compliance Mechanism

In attaching a train of detailed logistical transactions, we can chronicle the gasket and gain an insight into its construction. Quality assurance is an upshot of this strategy, as is a close-up of the raw materials used in the fabrication process. Lot and batch control often partners this asset, which only serves to underscore the importance of this mechanically-oriented biographical data. Used for recalls, quality assurance documentation, and for supplier/manufacturer relationships, a gasket material traceability program guarantees an informed engineer always has access to an up-to-date source file of all gasket materials and the manufacturing chains used in the fabrication process.

How Important is Traceability?

If the source of a critical component, especially a gasket, is cut out from this long chain of events, then there’s no way to assess the quality of the product. Risks increase because the sandwiching layer between two flanges is suddenly perceived as a weak link. The paperwork attached to the seal helps, of course, but only a properly stamped traceability code can safely guarantee function as it relates to a current application.

Gaskets should always have an attached history, one that’s indelibly and physically bonded to the seal. Once deciphered, it can be traced through multiple supply chains, all the way back to the fabrication workshop and the original source material.

Over the years, tough operating environments have challenged our engineers by introducing more pressure variables and higher temperatures. Mechanical assemblies use strong alloys and smart designs to deal with these stresses, but there’s still the surface-to-surface junctions between each component to handle. Substance-fatiguing fuels and corrosive oils aren’t about to go away, after all, not when they power every industrial domain. We need a better solution, the incorporation of elastometric gaskets, and a highly compressible polymer that retains its seal even when these harsh forces are at their peak.

Juncture Sealing

Gaskets provide a powerful seal between two surfaces, but they will fail if their design isn’t up to the job at hand. Manufactured to function with assurance when operating conditions are at their toughest, elastometric gaskets fill their feature set with aptitudes that other sealing materials sadly lack. The shaped seals compress superbly when flange fasteners are fully tightened, but this compressibility factor does not undermine the elasticity of the material, meaning it will spring back into shape when the two surfaced are opened for maintenance. Additionally, the viscosity of the polymer ensures the rubber-like substance conforms to every irregular outline of the two mating parts, which enhances the seal and eliminates any possibility of leakage.

Fluid Managing Attributes

The above passage relates to the mechanical talents of this gasket medium. It compresses and decompresses, remains flexible as high pressures are applied. Next, gaskets made from this multi-talented chemical compound also sport a number of essential environmental gifts. The molecular structure of the tough elastomer is indeed flexible and rubber-like, but its chemical bonds are fixed in other ways. The gaskets won’t crack or become brittle when temperature spikes are part of the application sphere. This means high temperatures won’t melt the substance and low temperatures won’t cause the tough material to stiffen and develop fractures. Similarly, elastometric gaskets don’t fail when caustic chemicals or fuels are in the pipeline. They’re also a logical choice for the geometrically detailed seals used in engine housings and mechanism fuel lines, as the polymer is a reliable performer when any of these aggressive liquids are part of the lifeblood of a working mechanical system.

Gaskets with elastomeric materials are viscous and elastic, soft and flexible, but they exhibit strong mechanical and chemical resistance features. Viton is a prime example of this high-performing substance, as are the fluoro-silicone and fluoroelastomer families that create a secure seal when vibration, oil, or challenging thermal events are part of the mechanism in question.