A handful of flow-determining characteristics guides the production of gaskets. Firstly, they’re fabricated to conform to a specified geometrical outline. Now, while the shape of each sealing product is an essential consideration, it’s the raw materials used in each situation that really makes the difference. Material selection affects every attribute, everything, right down to the integrity of the mechanical seal and its aptitude for handling different fluid-conducting scenarios.

Popular Polymers

PTFE (Polytetrafluoroethylene) products are equipped with excellent mechanical properties. They don’t react to chemicals but do exhibit superior thermal insulation properties, which makes the polymer an ideal match for hot fluids. Next, Nitrile and Viton enter the common materials list. These synthetic materials are frequently used in fuel pipe seals and joint seals, the flanged pipe sandwich fillers that resist the corrosive effects of petroleum oils. Other polymers in this class include toughened engineering plastics, including members of the urethane family, materials that are designed to offset the effects of all of the negative influences covered above while adding other features. Note, these materials can be graded or fabricated as composites to add even more versatility to the polymer solution.

Carbon and Metal-Reinforced Gaskets

In fabricating materials that satisfy the rigorous demands associated with the aerospace industry and other cutting-edge domains, we turn to graphite, a material that retains dimensional stability and seal integrity when high pressures and higher temperatures are part of the mix. And, depending on project parameters, we can escalate this approach by turning to carbon fiber reinforcement, Teflon additives, Kevlar substitutes, or even stainless steel wire mesh, additives that really inject mechanical strength into the product. Suitable for cryogenic applications or just plain armoured to excel in tough industrial settings, the addition of such reinforced assets are highly beneficial when it comes to temperature extremes and huge pressure differentials.

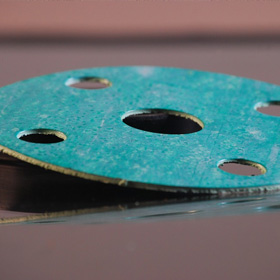

Non-Asbestos Compressed Fiber

When specially compressed fibers are partnered with proprietary polymer linings, gaskets gain super-fortified capabilities. Able to function under huge stresses, the toughened fibers pass super-heated steam and corrosive acids with equal efficiency. Asbestos is absent from the material makeup, which is a big bonus. But do take note, the compressed fiber construct actually uses many of the materials already covered earlier in this article, including Kevlar aramids, graphite, and complementary PTFE mixtures.

The design of these sealing products starts with paper and felt, cork and foam, but gasketing technology then quickly escalates to cope with heated, pressurized, and caustic fluids.

The use of mechanical equipment is rarely a dry affair. We all know of a machine that pushes volumes of liquid or gas, know about fuel pumps and water sump pumps. Even the machines that don’t pump fluids, well, they rely on liquids, too. Lubricating agents and special coolants fill their chambered profiles, and they need special seals to keep the fluid contained. Gaskets and sealing washers are the mechanical solutions to this fluid isolating quandary. The ring of rubber or engineering plastic used to form a standard gasket sits snugly between two surfaces, aiding in the creation of a viable seal. Let’s take a closer look at gasket applications and uses for sealing washers.

Gasket Applications

There’s a good chance that gaskets are in play within any assembly of parts. Car engines, as one popular example, employ various fluids, and each liquid must stay within its flow path, even if it’s chemically active or running hot. Fuel lines and engine components use variously shaped seals, gaskets that vary wildly from the standard circular shape so that engine blocks can be sealed against cylinder heads. Super-hot coolant flows through the radiator. Oil is kept in check, and the entire package of parts functions under pressure, all thanks to numerous gaskets. Meanwhile, back at home or even under the home, gaskets fill the sliver of space between pipe flanges and flatten imperceptibly as large fasteners bond one pipe to the next. These few examples define the form as either a flexible ring or a wide sheet with special cutouts, all the better to slide large mechanical engine components together.

Introducing Sealing Washers

In describing the usage domains of gaskets and sealing washers, it’s tempting to give the spotlight to the former item and append the description with an addendum on special washers, but sealing washers are very important fastening aids. For example, the hardened ring, metal on one side and rubber on the other, is designed to be inserted between a screw bolt or screw head and a threaded hole. As the fastener tightens, it presses down on the small ring and forms a secure lock, one that stops the fastener from loosening. General applications include vibration-resistant fasteners, oil drain plugs, and construction projects, the surfaces that benefit from a strong locking action and a fluid-resistant seal.

Gaskets and sealing washers cancel vibration, provide secure fastener locking features, and stop fluids from leaking, and all thanks to the addition of a suitable amount of mechanical force as threaded fasteners tighten.