Let’s hone in on a specific case study, a threat profile that shows how overheating and extreme temperatures can affect gasket performance. Yes, in the long run, different mechanical sealing families are fabricated from advanced materials, and they’re designed to handle compressive forces while faithfully confining corrosive fluids, but what happens when that fluid is imbued with energy? What happens when there’s a powerful thermal component flowing inside the pipework?

The Effects of Heat

High temperatures are just part of the daily grind here. Hot water and hotter spouts of steam course down restricted channels. Like a near sentient elemental force, the heated fluid seemingly looks for an exit. The generated energy, locked inside the coursing medium, attacks the interspersed seals within the hot pipeline. The effects of the thermal discharge are catastrophic. They include swelling and hardening, material changes that corrupt structural integrity. Unless, the gaskets are built to tolerate such temperature extremes, failure is likely.

When Adverse Temperatures Prevail

A gasket that’s equipped with an elastomeric function will seal readily and fill fine surface deformities when two flanges come together, but this mechanical asset degrades dramatically when the ring of sealing material is exposed to more thermal energy than it is rated to tolerate. The material begins to bake. It hardens and loses elasticity. The temperature seesaws, which then causes the hardening gasket to crack. Leaks are quick to take advantage of this new escape route. We’re looking at a brittleness transition that’s destined to cause leaks and subsequent performance plunges, for the closed system is suffering from a hemorrhaging event, a leak that will compromise the formerly pressure-secured pipework.

Assessing Material Deformations

Much of what’s been covered could be considered a generalization. Make no mistake, thermal energy is destructive when not contained properly, but the effects differ according to the materials used in each system. Certain gaskets use thermoset materials but others opt instead for a thermoplastic core. Setting materials tend to shrink and harden, so they crack. Plastic-like variants, on the other hand, melt and deform. Creep and relaxed fits generally prosper when the material deforms, so the tight flange seal loosens. Again, a nasty leak is likely and system performance losses are an unavoidable result of this material slimming effect.

Select strong engineering plastics and metal-reinforced products to avoid performance-debilitating events. Thermally capable plastics and deformation-resistant alloys don’t contract or expand, don’t harden or become brittle, and they will always stay the course, no matter how hot the situation becomes.

Gaskets are among the hardiest of products, so why not reuse an old one if it’s doing nothing else? It’s a tempting proposition, especially since these seals are fabricated from indefatigable materials. But doesn’t it make more sense to spend a few dollars on a replacement? The answer to that important question isn’t quite as clear-cut as you’d suppose, and here’s why.

The Usability Factor

If a previously used gasket still appears functional, the product could very well be pressed back into service. The material on this hypothetical seal is dimensionally unaltered and physically undamaged, so why shouldn’t it be inserted between two new mating surfaces? If it’s still compressible and still retains its original thickness, then reuse is possible but not certain.

The Uncertainty Principle

Reliability ranks just as highly as usability as a determining factor, but there’s no real way of assuring this condition. The component looks as structurally viable as ever. It compresses and seats flawlessly, but looks can be deceiving. High temperatures may have adversely influenced the material, weakened the fabric until it no longer satisfies its original product specs. On the other hand, if the previous joint didn’t experience intense thermal spikes or encounter chemically reactive substances, then there’s every chance it will work according to its original design specifications. In the end, we’re looking at a judgment call.

Apply a Differential Approach

Resolve the matter by playing devil’s advocate for the day. In taking on both sides of this debate, you compare the benefits associated with both options. In the reuse corner, this economical solution is advocated when the product isn’t damaged or structurally altered. There’s no way to ensure structural viability, but a look at the original application does tilt the case in favour of reuse if high temperatures and caustic chemicals weren’t part of the processing setup. If the gasket is suspect, then replace it. Suspect products are those that have been used in abrasive environments, or they’re obviously damaged, swollen, or material-fatigued.

This is a subjective topic, but a healthy pinch of objectivity is helpful. Yes, reuse the gasket if it’s structurally intact, but also address the application domain question. Next, replace the part if fluid saturation problems are obvious. Then, as far as final recommendations go, gauge the quality of the seal while keeping a rein on subjective thinking. Act objectively, and make the final choice based on collected application data, an impartial evaluation that inspects every aspect of the potentially reusable gasket.

Proactive design methodologies manufacture gaskets from specially selected materials when chemical resistance is a major issue. Step back from the pipes and storage containers for a minute to see why this design principle is so important. Caustic compounds are coursing through these metal channels. They react aggressively with certain materials. How does a chemical resistance guide stop this aggressive reaction from weakening a gasket?

Modifying Gasket Properties

If seal technology can manufacture products that target heat extremes and intense pressure differentials, then that same know-how can produce seals that can handle different chemical families. Organic fuels and viscous lubricants adhere to this principle, as do acidic compounds. All that’s required is a technical specification sheet and an aptitude for expert material selection. The gasketing material is then manufactured from a chemically-neutral compound, a polymer or metal that won’t react with the conveyed fluid.

Chemical Resistance Counts

Unequivocally, the seals in a chemical line are beyond important. If corrosive chemicals leak because the wrong material has been selected for the joint seal, the escaping fluid could form a toxic cloud and poison the local environment. We’re dealing in “could’s” and “maybe’s” so far, but the damage will cause a catastrophe. At best, imagine the toxic fluid damaging the environment and getting into the local water supply. At worst, well, if the mix is combustible, then a catastrophic explosion will destroy everything in its path.

Determine Resistance

A sound understanding of material properties and the application domain are mandated. Compatibility reference charts are available from material sources, so use this resource before making a commitment to the project. For instance, PTFE holds a special place in a design engineer’s heart because of its chemically neutral structure, but it can weaken when it’s exposed to a fluorinating agent. This example only serves to prove the principles we’re stressing. In short, even the strongest material will fail when it meets its chemical “Kryptonite.” In conclusion, opt for a non-reactive gasket, but do realize that the term “non-reactive” is relative. Its reliability depends on the conveyed or stored chemicals and their reactive properties.

A seal, when compressed and pressed into service, should never be viewed as the weak link in the pipeline. Instead, it must be designed to excel. This challenging feat is made possible by installing the product properly and ensuring that it’s designed to endure, no matter the abrasive chemical within. Always evaluate the chemical resistance of gaskets when working with corrosive and toxic materials.

Intelligent design practices form the spearhead of any design process. In the case of the various materials used for making gaskets, fabrication development takes its lead from the eventual application. In essence, nothing is set in stone until certain important factors are determined. These client-stipulated specifications cover mechanical operating conditions and thermal factors, plus there’s the chemical composition of the interred fluid to consider.

Fluid Conveyance Deliberations

Volatile chemicals assault fluid transmission joints. Heat and pressure extremes then go to work on pipe seals and housings. They’re assisted by fastener pressure and half a dozen other compressive elements. Even water can be an unsolicited threat here when time works with the liquid to oxidize parts. Gaskets prevail in all of these scenarios when they’re made of the right material.

Moderately Capable

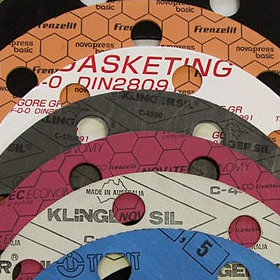

Various fabrics are used to manufacture the right seals for specific applications. They start on the most innocuous level with granulated cork and paper films. The substrate fabrics are not pressure rated, but they do resist oils and certain fuels. Cellulose-based paper, for example, is used in many low horsepower engines to repel oily substances and semi-viscous fuels. Cork variants also bind to rubber backings to add vibration compensating features to the mix.

Fabric and Foam

When used in their base form, there’s little to be said about the mechanical aptitude of this product. Nylon yarn and urethane linings are typically die cut into complex shapes. The weave incorporates conducting metals so that the finished fabric sheet can be used as an EM (electromagnetic) shield. Important as this electronics-oriented application undoubtedly is, the fabric only realizes its ultimate purpose when it’s paired with strong polymers.

Fabric-Reinforced Gaskets

Polyester and rayon are two of the more common woven threads in use on this occasion. They bind EPDM, Neoprene, and other chemically neutral polymers. In effect, the soft rubbers compress efficiently while the fabric stops flex cracks. It reinforces the polymer. This composite gasketing type is also known as a cloth inserted sheet.

The tip of our metaphorical spear is reserved for our concluding paragraph. The materials used here include high-end silicones and the polyurethane family. From here, the synthetically engineered materials divide further to include chemically resistant branded variants and Teflon-strengthened PTFE. Finally, crowning these elastomeric and pliable synthetics, comes spiral wound gaskets. They sit up top with metal gaskets, alloys that are relatively soft but require immense compressive force if a proper seal is to be achieved.

Gasket fabrication technology produces reams of high-quality joint seals, but they’re not exactly designed to be dimensionally precise. After all, their primary function is to create an unbreakable seal, not to advance some difficult-to-achieve structural ideal. Of course, this idealised form is available, but only compression controlled gaskets can properly foster such accurate outlines when extreme tightening forces are doing their utmost to corrupt a gasket’s dimensionally assured outlines.

What are Compression Controlled Gaskets?

This sealing medium compresses intelligently when fastening forces exert great force on a joint. In other words, the gasket spreads smartly when it’s sandwiched between two sealing faces. Imagine the benefits of this non-compressible material. It won’t spread beyond the boundaries of delineated gasket space, so no untidy edges are exposed to the internal or external pipe joint. This is an especially handy feature when internal flow conditions are sensitive to material interference.

Flush Unions Support Sensitive Fluid Conditions

As the gasket lays flush at the joint union point, no “dead spots” will form. Instead, the fluid is conducted smoothly from one pipe section to the next. This singular flow-smoothening characteristic is viewed as highly important in certain applications. Subsequently, the food and pharmaceutical industry both employ compression controlled gaskets because system engineers are upholding a regulated hygiene methodology. Basically, the addition of an intersection aid that creates a seamless seal serves to reinforce hygiene-centric design practices.

Creates Extrusion-Free Unions

A vulcanised Ultem resin regulates the compression force applied by mechanical fasteners. The gasket material within the ring of non-compressible resin then conforms to the ferrules of the mechanical bore juncture to form a flush interface, an uninterruptible bridge between system-critical fluid channels. The design is recognized as a perfect fit for sanitary-sensitive applications, so it’s found in conduits that carry foodstuffs and beverages. Likewise, many chemical and medical fields employ the gasket when seeking to eliminate the inline dead spots that could provide shelter for bio-contaminants. Interestingly, the lifespan of this sealing product is also extended by its flattened profile, for no stray edges are protruding into the flow, so the gasket doesn’t wear as quickly as general-purpose sealing products.

These are specialised gaskets. They’re designed to excel in situations where dimensional accuracy is a major asset. A tabbed kit takes sanitary considerations to the next logical feature plateau by ensuring finger contact is minimised. All handling and installation work is done via the tabs, all so that a hygiene-oriented union is fully realised.